Categories

Contact Us

Tel: +86 18916636634

E-mail: sales03@leading021.com

Address: No.517,Xinlai Road,Xuhang Town,Jiading District,Shanghai,China

LDK-DI-250

This new reverse osmosis deionized water filter from china delivers exceptional water purification for laboratory and industrial applications. Combining advanced membrane technology with efficient deionization, it offers the reliability and performance of a quality reverse osmosis deionized water filter, providing ultra-pure water solutions for critical processes and research requirements.

- Commodity name: LDK-DI-250

- Product Description

-

Specification

Product feature

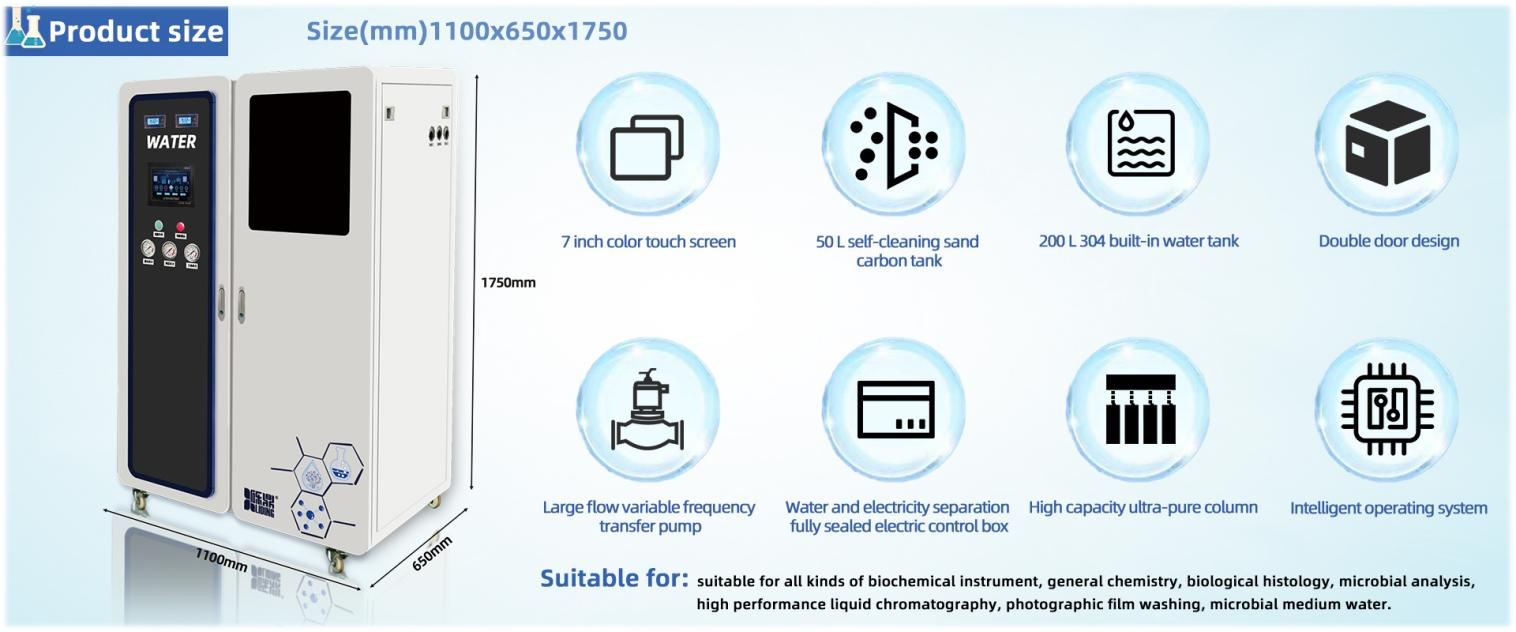

➣ 7-inch touch color screen control interface, manual automatic mode switch

➣ The host is built in a 200 L 304 stainless steel level control tank

➣ Built-in large flow frequency conversion transmission module, flow rate, water pressure automatic adjustment to meet all kinds of water demand

➣ Built-in self-flushing type large capacity sand carbon tank, tank diameter 25 cm height 1.6 meters. Pretreatment is used for 1.5 years without core change

➣ Water and electricity separation technology, small square box fully sealed electric control system

➣ The working state of the equipment can directly see the real-time online monitoring of the working pressure and post-pump pressure, and the online monitoring of water inlet and double conductivity of water quality

➣ The wheel foot strip at the bottom of the equipment can be moved and fixed quickly

➣ Side and back buckle type removable door panel to facilitate the replacement of later consumables

➣ Double door design internal structure is clearly visible for maintenance and equipped with a special key

➣ Ergonomic design, beautiful machine meets GLP requirements

➣ Gift of the TDS water quality test pen

➣ Equipped with super-large capacity purification tank supplies are more durableParameter

This new reverse osmosis deionized water filter from china provides researchers and technicians with superior water purification through its 250-liter per hour capacity that meets demanding laboratory and industrial needs. The system achieves impressive ion rejection rates of 97-99% with new RO membranes and removes over 99% of organic matter, particles, and bacteria, producing ASTM Type II grade water with resistivity of 10-16 MΩ·cm and conductivity below 0.1 μS/cm. Users benefit from the complete system configuration including host machine, purification columns, 100L pressure tank, and TDS pen that enables immediate operation and continuous monitoring of water quality.

Engineered for reliable performance, this quality reverse osmosis deionized water filter features efficient energy consumption (48-72W) and compatibility with standard urban tap water sources. The comprehensive purification capabilities make it suitable for diverse applications from laboratory experiments and reagent preparation to instrument water supply and industrial processes. As a new reverse osmosis deionized water filter from china, it represents advanced water treatment technology that delivers the trusted performance of a quality reverse osmosis deionized water filter while providing user-friendly features that ensure consistent ultra-pure water production for scientific and industrial applications.

Filter function

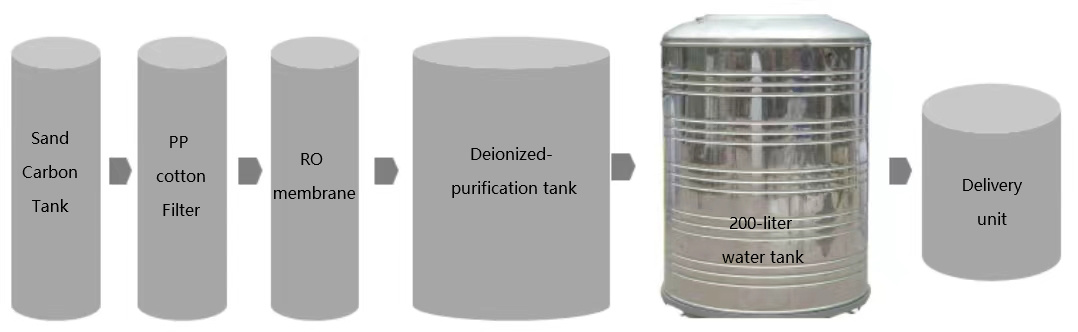

Process

Product consumables list

Note: The filter replacement cycle in the table is estimated based on previous customer experience. It is only a suggestion. The specific period is determined by the water quality.

Get A Quote

Related Products