Understanding Laboratory Ultrapure Water Systems: Essential Insights for Industrial Applications

Time:

Aug 15,2025

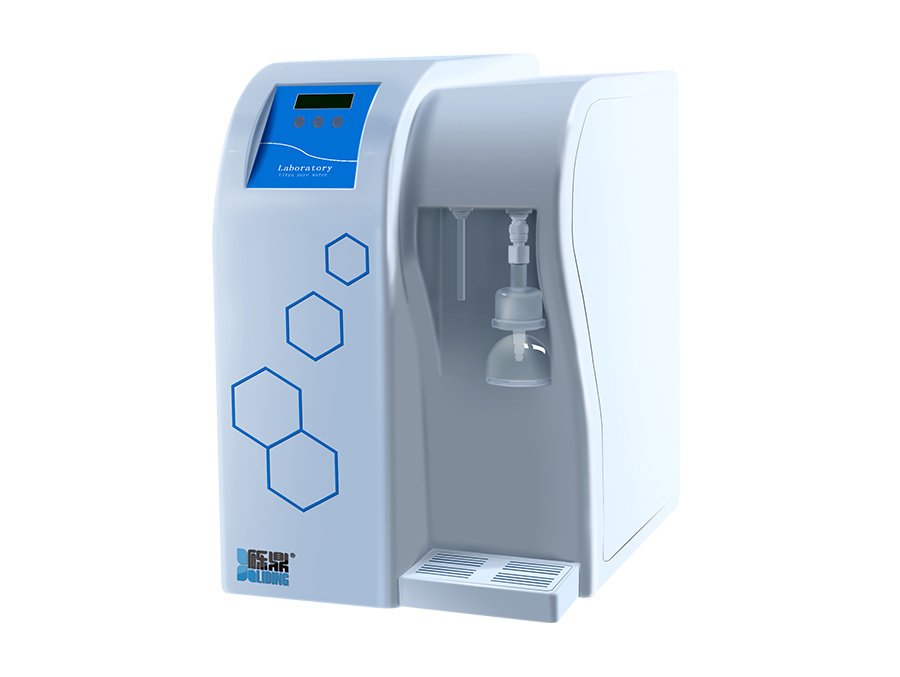

In various industries and research laboratories, the need for ultrapure water is critical. A laboratory ultrapure water system is designed to produce water that meets stringent purity standards, essential for numerous applications such as analytical chemistry, pharmaceuticals, and semiconductor manufacturing. Understanding the components and functions of these systems can significantly enhance operational efficiency and product quality.

Ultrapure water is characterized by its low levels of contaminants, including ionic species, organic compounds, and bacteria. A laboratory ultrapure water system typically consists of several stages of purification, often integrating reverse osmosis, deionization, and ultraviolet (UV) sterilization. Each stage plays a vital role in removing impurities to achieve the desired level of purity.

The first stage, reverse osmosis, uses a semi-permeable membrane to separate water from contaminants. This step effectively removes up to 99% of dissolved salts and organic molecules. Following this, deionization (DI) removes any remaining ionic contaminants through ion exchange resins, ensuring the water meets the necessary specifications for high-purity applications. Finally, UV sterilization is employed to eliminate any microorganisms that may have survived the previous treatment stages, securing the water's quality.

One of the critical benefits of a laboratory ultrapure water system is its ability to supply consistent quality water, which is crucial for reproducibility in experiments and processes. The system’s advanced monitoring capabilities often include real-time measurement of resistivity or conductivity, offering users insights into water quality and helping to identify when maintenance is needed.

When considering a laboratory ultrapure water system, several factors should be evaluated. These include the required water quality, production rate, and the specific applications intended for the water. Furthermore, understanding the operational costs, including maintenance and consumable replacement, is vital for effective budgeting and planning.

In summary, laboratory ultrapure water systems are indispensable in various industrial applications. They ensure the availability of high-quality water necessary for critical processes while providing a reliable and efficient solution for water purification needs. By investing in a well-designed ultrapure water system, organizations can enhance their research capabilities and improve the reliability of their products.

Ultrapure water is characterized by its low levels of contaminants, including ionic species, organic compounds, and bacteria. A laboratory ultrapure water system typically consists of several stages of purification, often integrating reverse osmosis, deionization, and ultraviolet (UV) sterilization. Each stage plays a vital role in removing impurities to achieve the desired level of purity.

The first stage, reverse osmosis, uses a semi-permeable membrane to separate water from contaminants. This step effectively removes up to 99% of dissolved salts and organic molecules. Following this, deionization (DI) removes any remaining ionic contaminants through ion exchange resins, ensuring the water meets the necessary specifications for high-purity applications. Finally, UV sterilization is employed to eliminate any microorganisms that may have survived the previous treatment stages, securing the water's quality.

One of the critical benefits of a laboratory ultrapure water system is its ability to supply consistent quality water, which is crucial for reproducibility in experiments and processes. The system’s advanced monitoring capabilities often include real-time measurement of resistivity or conductivity, offering users insights into water quality and helping to identify when maintenance is needed.

When considering a laboratory ultrapure water system, several factors should be evaluated. These include the required water quality, production rate, and the specific applications intended for the water. Furthermore, understanding the operational costs, including maintenance and consumable replacement, is vital for effective budgeting and planning.

In summary, laboratory ultrapure water systems are indispensable in various industrial applications. They ensure the availability of high-quality water necessary for critical processes while providing a reliable and efficient solution for water purification needs. By investing in a well-designed ultrapure water system, organizations can enhance their research capabilities and improve the reliability of their products.

RELATED NEWS