Choosing the Right Ultra Pure Water Machine for Your Business Needs

Time:

Aug 12,2025

Choosing the Right Ultra Pure Water Machine for Your Business Needs

Table of Contents

- Understanding Ultra Pure Water

- The Importance of Ultra Pure Water in Various Industries

- Types of Ultra Pure Water Machines

- Key Factors to Consider When Choosing an Ultra Pure Water Machine

- Leading Manufacturers of Ultra Pure Water Machines

- Cost Analysis: Budgeting for Your Ultra Pure Water Machine

- Common Misconceptions About Ultra Pure Water Machines

- Frequently Asked Questions

- Conclusion

Understanding Ultra Pure Water

Ultra pure water (UPW) is water that has undergone extensive purification processes to remove all contaminants, including ions, organic and inorganic particles, and microorganisms. It is vital in industries such as pharmaceuticals, electronics, and power generation, where the smallest impurities can affect product quality and safety. In this highly regulated environment, the demand for ultra pure water continues to grow, making the choice of an appropriate purification system critical.

The Importance of Ultra Pure Water in Various Industries

Ultra pure water is not just a luxury; it is a necessity in several sectors. In the pharmaceutical industry, for instance, UPW serves as a solvent for drug formulation and cleaning agent for equipment, ensuring compliance with stringent regulatory standards. In electronic manufacturing, ultra pure water is essential for the production of semiconductors and circuit boards, where impurities can lead to defects. The power generation sector relies on UPW to ensure the efficiency and longevity of its systems, as impurities can cause scaling and corrosion. Thus, understanding the importance of ultra pure water sets the stage for choosing the right machine.

Types of Ultra Pure Water Machines

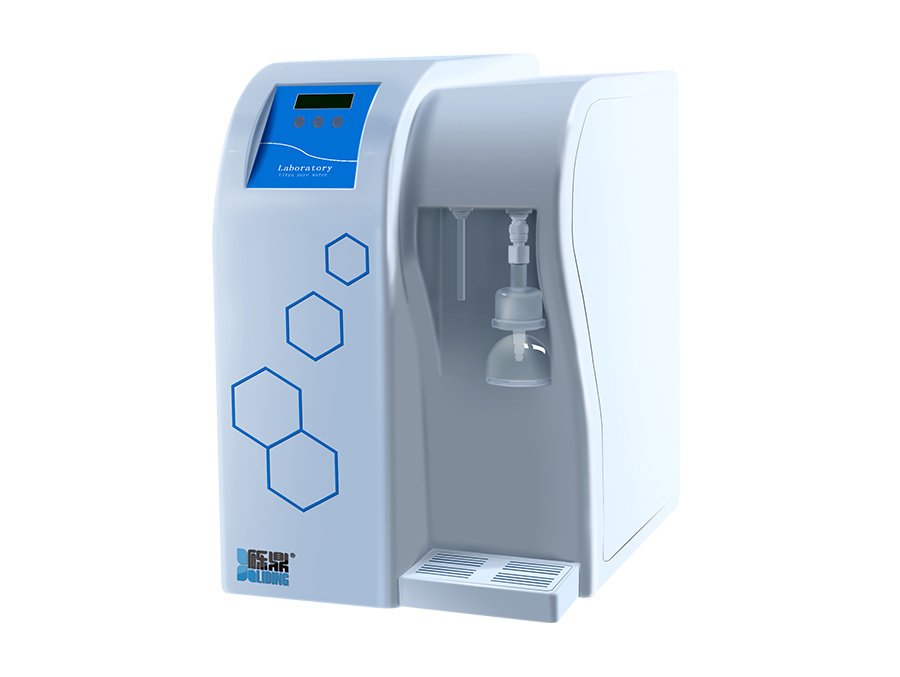

When it comes to ultra pure water machines, various technologies can be employed, each with its advantages and applications.

Reverse Osmosis Systems

Reverse osmosis (RO) systems utilize a semi-permeable membrane to separate impurities from water. This technology is effective in removing ions, sediments, and other contaminants, making it one of the most popular choices for ultra pure water production. RO systems can be configured in different sizes and capacities, catering to both small-scale and large-scale operations.

Distillation Systems

Distillation involves heating water to create steam and then cooling the steam to produce condensate. This method effectively removes most contaminants, including heavy metals and biological impurities. While highly effective, distillation systems may have higher energy consumption and longer processing times compared to other technologies.

Electrodeionization Systems

Electrodeionization (EDI) combines ion exchange and electrochemical processes to remove ionic contaminants from water. This system is particularly useful for applications requiring high purity levels and continuous operation, as it often eliminates the need for chemical regeneration of ion exchange resins.

Key Factors to Consider When Choosing an Ultra Pure Water Machine

Selecting the right ultra pure water machine requires careful consideration of several factors to ensure it meets your business needs.

Water Quality Requirements

Understanding your specific water quality requirements is paramount. Different applications will have varying purity standards (e.g., conductivity, total organic carbon, and bacteria counts). Make sure to assess the specifications thoroughly to find a machine that can meet or exceed these standards.

Production Capacity

Evaluate your business’s daily water demand. Ultra pure water machines come in various capacities, and selecting one that matches your production needs will help prevent bottlenecks in your operations. Consider the peak demand and ensure the system can cope with fluctuations.

Space and Installation

Installation requirements and available space are often overlooked yet critical factors. Some ultra pure water systems require specific plumbing and electrical configurations. Assess your facility's layout and ensure there is adequate space for the machine, including considerations for future expansion.

Maintenance and Support

Regular maintenance is crucial to the longevity and efficiency of any ultra pure water system. Evaluate the manufacturer’s support offerings, including warranty terms, availability of replacement parts, and customer service responsiveness. A reliable support system can save you time and money in the long run.

Leading Manufacturers of Ultra Pure Water Machines

The market for ultra pure water machines is populated by several leading manufacturers. Brands such as MilliporeSigma, Thermo Fisher Scientific, and Pall Corporation are known for their high-quality systems that cater to various industries. Researching these manufacturers will provide insights into their technology, customer reviews, and after-sales service, aiding in your decision-making process.

Cost Analysis: Budgeting for Your Ultra Pure Water Machine

Cost is often a decisive factor in selecting an ultra pure water machine. Initial purchase price, installation costs, and ongoing maintenance expenses all contribute to the overall budget. While cheaper machines may seem appealing, they could lead to higher operational costs due to lower efficiency and more frequent breakdowns. It’s essential to evaluate the total cost of ownership rather than just the upfront price.

Common Misconceptions About Ultra Pure Water Machines

Misinformation about ultra pure water machines can lead to poor purchasing decisions. One common misconception is that all purification systems can provide the same quality of water. However, the effectiveness of each technology varies significantly based on the contaminants present in the source water. Another myth is that ultra pure water systems are too costly to operate. In reality, when considering the operational efficiency and life cycle costs, these systems can be quite economical.

Frequently Asked Questions

1. What is the difference between ultrapure water and distilled water?

Ultrapure water has undergone additional purification processes to eliminate all contaminants, achieving higher purity levels than distilled water, which may still contain some impurities.

2. How often should I service my ultra pure water machine?

Regular maintenance is recommended every 6 to 12 months, depending on the manufacturer's guidelines and the usage level of the machine. Routine checks can prevent costly downtime.

3. Can I use tap water in an ultra pure water machine?

Using tap water is generally not recommended, as it can contain various impurities that could compromise the efficacy of the purification process.

4. What industries benefit most from ultra pure water machines?

Industries such as pharmaceuticals, electronics, and power generation are the primary beneficiaries, as the quality of their products is highly dependent on the purity of water used in their processes.

5. Are there regulatory standards for ultra pure water quality?

Yes, various industries have specific regulatory standards, such as those set by the U.S. Pharmacopeia for the pharmaceutical industry or the International Electrotechnical Commission for electronics manufacturing.

Conclusion

Choosing the right ultra pure water machine is a critical decision that can significantly impact your business's operational efficiency and product quality. By understanding the various technologies available and evaluating your specific requirements—such as water quality, production capacity, space, and maintenance—you can make an informed choice that aligns with your operational goals. Take the time to research leading manufacturers and consider the total cost of ownership to ensure a wise investment. With the correct ultra pure water machine, your business can enhance its productivity and maintain the highest quality standards.

RELATED NEWS