The Crucial Role of Ultrapure Water in Advanced Laboratory Research

Time:

Aug 06,2025

The Crucial Role of Ultrapure Water in Advanced Laboratory Research

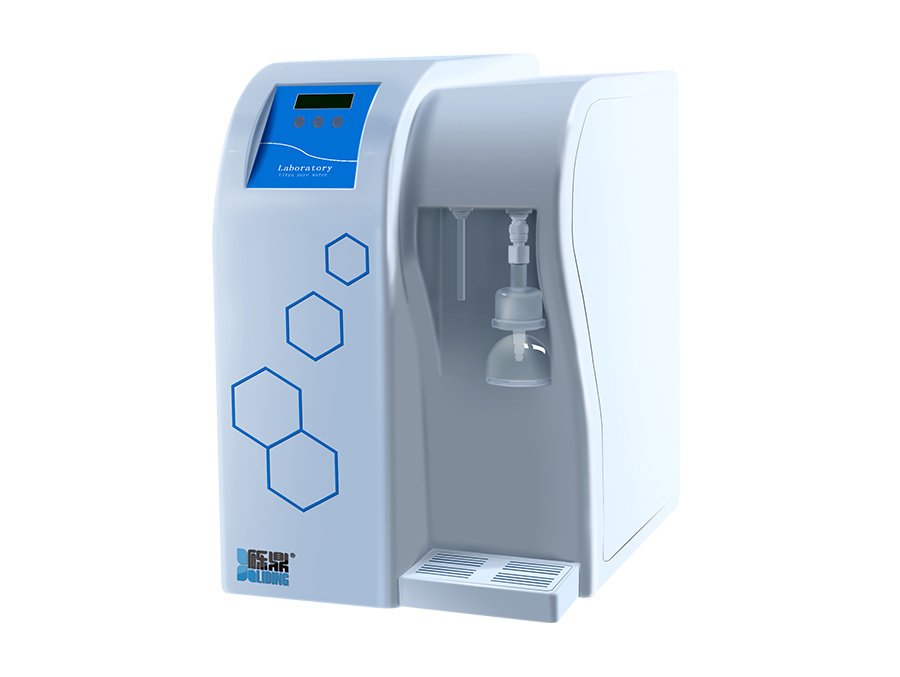

Table of Contents

- 1. Introduction to Ultrapure Water

- 2. Why Ultrapure Water is Essential in Laboratories

- 3. Key Applications of Ultrapure Water in Research

- 4. How Ultrapure Water is Produced

- 5. Quality Standards for Ultrapure Water

- 6. Proper Storage and Handling of Ultrapure Water

- 7. The Impact of Ultrapure Water on Research Outcomes

- 8. The Future of Ultrapure Water in Scientific Research

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Ultrapure Water

In the realm of advanced laboratory research, **ultrapure water** serves as a foundational element, pivotal for ensuring the integrity and accuracy of experimental results. This water type is distinguished by its exceedingly low levels of impurities, making it indispensable across various scientific disciplines. From chemical synthesis to biological experiments, ultrapure water's unique properties facilitate precise measurements and reliable outcomes.

2. Why Ultrapure Water is Essential in Laboratories

The significance of ultrapure water cannot be overstated. It is essential for several reasons:

2.1 Purity and Precision

In laboratory settings, even minute contaminants can skew results. Ultrapure water minimizes the risk of contamination, ensuring that experiments are conducted under optimal conditions. This purity is critical in fields such as **pharmaceuticals**, where precision is paramount.

2.2 Compatibility with Sensitive Equipment

Many analytical instruments, including mass spectrometers and chromatographs, require ultrapure water to function accurately. Using contaminated water can lead to equipment malfunction or erroneous data, underlining the need for stringent purity standards.

2.3 Regulatory Compliance

Numerous industries adhere to strict regulations regarding water quality. Using ultrapure water aids laboratories in complying with these regulations, ensuring that all research conducted meets industry standards.

3. Key Applications of Ultrapure Water in Research

Ultrapure water finds a wide array of applications in laboratory research. Some of the most notable include:

3.1 Chemical Analysis

In chemical analysis, ultrapure water is used to prepare reagents and dilutions, facilitating accurate and reproducible results.

3.2 Biological Research

In biological experiments, ultrapure water is crucial for preparing culture media, buffers, and solutions to maintain cell integrity and viability.

3.3 Semiconductor Manufacturing

Ultrapure water is also instrumental in the semiconductor industry, where it is used for rinsing wafers and cleaning equipment, as any impurities can significantly affect product quality.

4. How Ultrapure Water is Produced

Producing ultrapure water involves several advanced purification processes, each designed to eliminate specific types of impurities:

4.1 Reverse Osmosis

Reverse osmosis is a common initial step in ultrapure water production. This process utilizes a semipermeable membrane to remove a vast majority of dissolved solids, organic molecules, and other contaminants from water.

4.2 Deionization

Following reverse osmosis, deionization is employed to remove ionized impurities. This process typically involves mixed-bed ion exchange resins that capture cations and anions, resulting in high purity.

4.3 Filtration and UV Treatment

Further purification can be achieved through microfiltration and ultraviolet (UV) treatment. Microfiltration removes fine particulates, while UV treatment disinfects the water by eliminating microorganisms, ensuring that it is safe for laboratory use.

5. Quality Standards for Ultrapure Water

To maintain the necessary quality, various standards govern ultrapure water production. These include:

5.1 ASTM and ISO Standards

Organizations such as ASTM International and the International Organization for Standardization (ISO) set benchmarks for water purity, specifying maximum allowable limits for different contaminants.

5.2 Conductivity Measurements

Conductivity is a critical measure of water purity. Ultrapure water typically has a conductivity of less than 0.055 µS/cm, indicating extremely low levels of ionic contaminants.

6. Proper Storage and Handling of Ultrapure Water

Even after its production, maintaining ultrapure water's integrity requires careful storage and handling practices:

6.1 Appropriate Containers

Ultrapure water should be stored in containers made of materials that do not leach contaminants, such as high-density polyethylene (HDPE) or glass.

6.2 Avoiding Contamination

It is crucial to minimize exposure to the environment during handling to prevent contamination from airborne particles or surface impurities.

7. The Impact of Ultrapure Water on Research Outcomes

The impact of ultrapure water on research outcomes is profound. Its use not only enhances the reliability of experimental results but also fosters innovation by allowing researchers to explore new avenues in their work without the worry of contamination.

7.1 Enhanced Reproducibility

By using ultrapure water, laboratories can achieve consistent results, vital for publishing and sharing findings with the scientific community.

7.2 Improved Product Quality

In industries such as pharmaceuticals and semiconductors, the quality of the final product is often directly linked to the purity of the water used in its production.

8. The Future of Ultrapure Water in Scientific Research

As technology advances, the methods for producing and utilizing ultrapure water will continue to evolve. Research into new filtration techniques and materials is underway, promising even greater efficiencies and purities.

8.1 Integration with Smart Technologies

Future ultrapure water systems may integrate with smart technologies, allowing for real-time monitoring of water quality and automated adjustments to purification processes.

8.2 Environmental Considerations

With growing environmental concerns, the development of sustainable ultrapure water production methods is essential. Innovations that reduce waste and energy consumption while maintaining high purity levels are on the horizon.

9. Frequently Asked Questions

9.1 What is ultrapure water?

Ultrapure water is water that has been treated to remove nearly all impurities, including dissolved salts, organic materials, and microorganisms, making it essential for various laboratory applications.

9.2 How is ultrapure water different from distilled water?

While distilled water is purified through boiling and condensation, ultrapure water undergoes advanced purification processes, including reverse osmosis and deionization, resulting in a much higher purity level.

9.3 What are the main uses of ultrapure water in laboratories?

Ultrapure water is primarily used in chemical analysis, biological research, and semiconductor manufacturing, where high purity is critical for accurate results.

9.4 How can I ensure the purity of ultrapure water in my lab?

Ensuring purity involves using appropriate production methods, regular quality testing, proper storage, and minimizing exposure to contaminants during handling.

9.5 What are the challenges associated with ultrapure water production?

Challenges include maintaining consistent purity levels, managing waste generated during purification, and ensuring sustainability in water production methods.

10. Conclusion

In conclusion, the role of ultrapure water in advanced laboratory research is both crucial and multifaceted. It serves as the backbone of many scientific endeavors, ensuring the accuracy and reliability of various applications. As we continue to push the boundaries of scientific knowledge, the importance of ultrapure water will only grow, necessitating ongoing advancements in its production and utilization methods. Embracing these innovations will aid researchers in achieving groundbreaking findings while adhering to stringent quality standards.

RELATED NEWS