Understanding the Importance of Laboratory Ultrapure Water Systems in Industrial Applications

Time:

Jul 12,2025

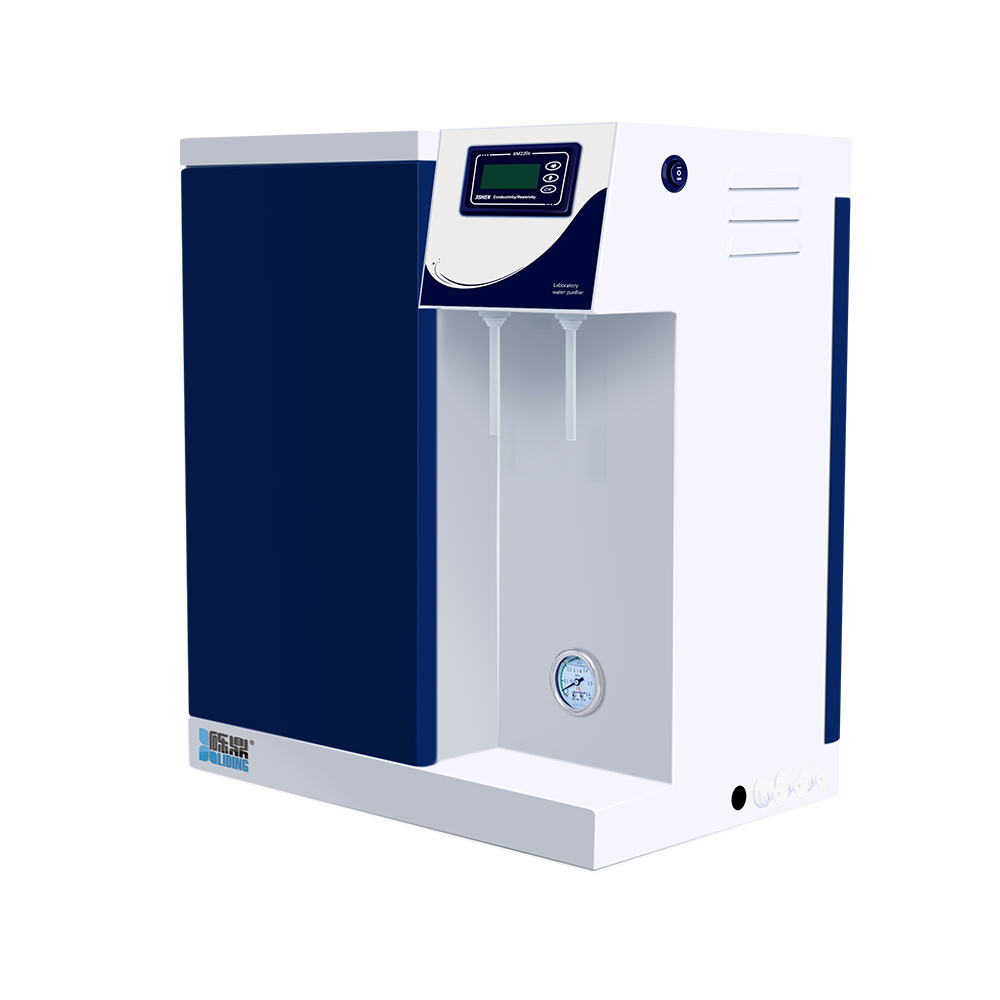

In the world of industrial equipment and components, especially in raw water treatment, laboratory ultrapure water systems play an essential role. These systems are designed to produce water with extremely low levels of impurities, meeting the stringent requirements of various laboratory and industrial applications. Understanding the functionalities and advantages of these systems can significantly enhance the quality of processes that rely on ultrapure water.

At the core of any laboratory ultrapure water system is the purification process, which typically includes several stages designed to remove contaminants. Initial filtration removes larger particulates, while subsequent treatments often involve reverse osmosis, deionization, and ultrafiltration. This multi-step approach ensures that the final output is devoid of ions, bacteria, organic compounds, and particulates, achieving resistivity levels typically over 18.2 MΩ·cm.

One of the primary benefits of utilizing a laboratory ultrapure water system is the enhancement of analytical results. In many laboratory settings, even trace contaminants can interfere with experiments, leading to inaccurate data. By using ultrapure water, laboratories can ensure that their results are reliable and reproducible, which is critical in research and development processes.

Moreover, laboratory ultrapure water systems are designed with efficiency in mind. They often incorporate smart technology that monitors water quality in real-time, allowing users to maintain optimal operational conditions. This feature helps in scheduling maintenance, which can prolong the life of the system and ensure consistent high-quality output. Additionally, these systems often come equipped with user-friendly interfaces that allow operators to easily control and adjust settings based on specific needs.

In industrial applications, the use of ultrapure water extends beyond laboratories. It is critical in processes such as semiconductor manufacturing, pharmaceuticals, and biotechnology, where water quality directly impacts product integrity. In these sectors, stringent regulatory compliance is essential, and ultrapure water systems help companies meet these requirements effectively.

The investment in a laboratory ultrapure water system is not merely about obtaining pure water; it is about securing the foundation for high-quality research and production. The long-term benefits include reduced costs associated with system maintenance and the potential for improved product yield and quality. As industries continue to evolve, the importance of reliable and high-purity water sources will only grow.

In conclusion, understanding the significance of laboratory ultrapure water systems is vital for professionals working in industrial equipment and raw water treatment. By investing in these advanced systems, organizations can ensure that they are equipped to meet the demands of modern scientific and industrial challenges, ultimately leading to greater innovation and efficiency.

At the core of any laboratory ultrapure water system is the purification process, which typically includes several stages designed to remove contaminants. Initial filtration removes larger particulates, while subsequent treatments often involve reverse osmosis, deionization, and ultrafiltration. This multi-step approach ensures that the final output is devoid of ions, bacteria, organic compounds, and particulates, achieving resistivity levels typically over 18.2 MΩ·cm.

One of the primary benefits of utilizing a laboratory ultrapure water system is the enhancement of analytical results. In many laboratory settings, even trace contaminants can interfere with experiments, leading to inaccurate data. By using ultrapure water, laboratories can ensure that their results are reliable and reproducible, which is critical in research and development processes.

Moreover, laboratory ultrapure water systems are designed with efficiency in mind. They often incorporate smart technology that monitors water quality in real-time, allowing users to maintain optimal operational conditions. This feature helps in scheduling maintenance, which can prolong the life of the system and ensure consistent high-quality output. Additionally, these systems often come equipped with user-friendly interfaces that allow operators to easily control and adjust settings based on specific needs.

In industrial applications, the use of ultrapure water extends beyond laboratories. It is critical in processes such as semiconductor manufacturing, pharmaceuticals, and biotechnology, where water quality directly impacts product integrity. In these sectors, stringent regulatory compliance is essential, and ultrapure water systems help companies meet these requirements effectively.

The investment in a laboratory ultrapure water system is not merely about obtaining pure water; it is about securing the foundation for high-quality research and production. The long-term benefits include reduced costs associated with system maintenance and the potential for improved product yield and quality. As industries continue to evolve, the importance of reliable and high-purity water sources will only grow.

In conclusion, understanding the significance of laboratory ultrapure water systems is vital for professionals working in industrial equipment and raw water treatment. By investing in these advanced systems, organizations can ensure that they are equipped to meet the demands of modern scientific and industrial challenges, ultimately leading to greater innovation and efficiency.

RELATED NEWS