The Role of Ultra Pure Water Machines in Environmental Sustainability

Time:

Jul 11,2025

The Role of Ultra Pure Water Machines in Environmental Sustainability

Table of Contents

- Introduction: Understanding Ultra Pure Water Machines

- The Importance of Water Purification in Sustainability

- What Are Ultra Pure Water Machines?

- The Technology Behind Ultra Pure Water Systems

- Environmental Benefits of Ultra Pure Water Machines

- Industrial Applications of Ultra Pure Water Machines

- Challenges in Implementing Ultra Pure Water Systems

- Conclusion: A Pathway to a Sustainable Future

- FAQs

Introduction: Understanding Ultra Pure Water Machines

Ultra pure water machines play a pivotal role in ensuring clean, contaminant-free water, which is essential for industries ranging from pharmaceuticals to electronics. As the global demand for clean water intensifies, these machines have emerged as vital tools for achieving environmental sustainability. They not only provide high-quality water but also minimize the ecological footprint associated with water treatment processes.

The Importance of Water Purification in Sustainability

Water is a precious resource that is increasingly under threat from pollution and overexploitation. Effective water purification is essential for safeguarding ecosystems and ensuring public health. Sustainable water management strategies must integrate advanced purification technologies, such as ultra pure water systems, to mitigate environmental impacts. These systems ensure that water is not only safe for consumption but also minimally disruptive to natural habitats.

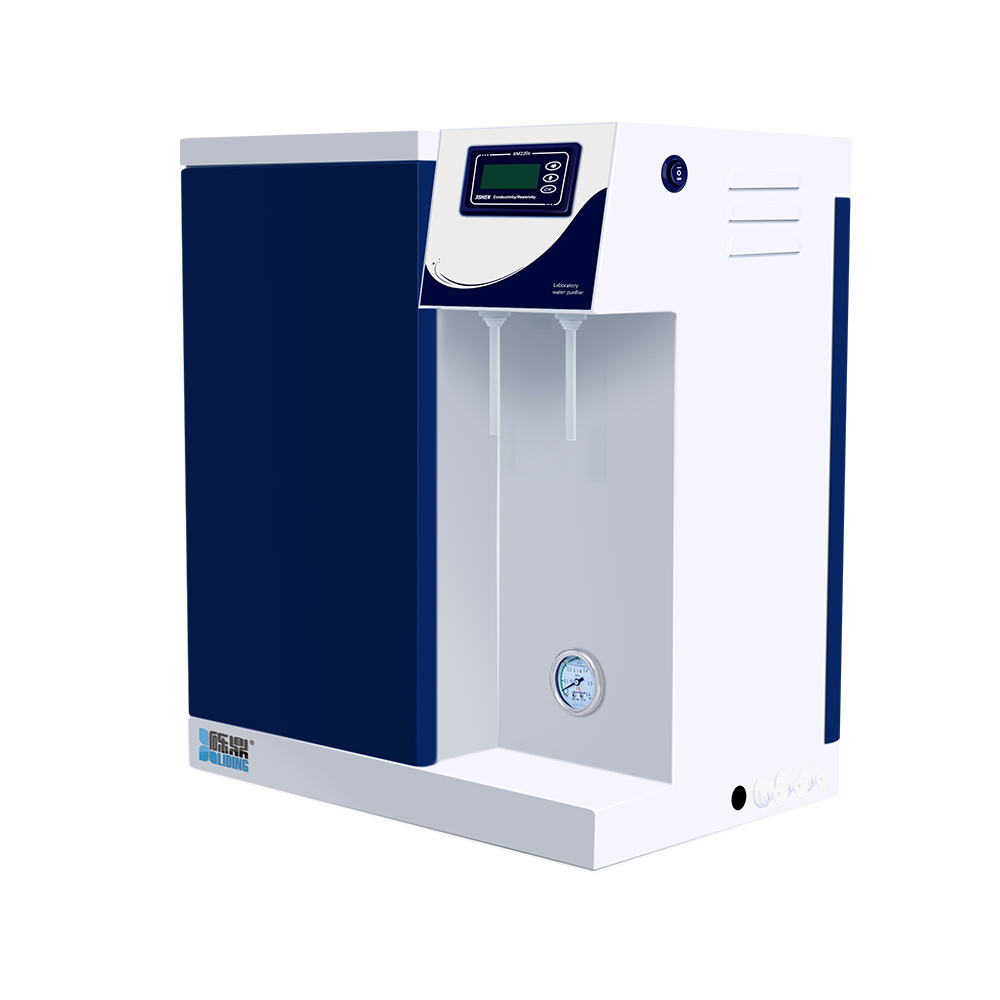

What Are Ultra Pure Water Machines?

Ultra pure water machines are specialized systems designed to remove impurities from water to achieve extremely high purity levels. These machines utilize advanced filtration and purification technologies, including reverse osmosis, deionization, and distillation, to eliminate contaminants such as bacteria, viruses, and particulate matter. The result is water that meets stringent quality criteria for use in sensitive applications where even trace contaminants can compromise product integrity.

Key Components of Ultra Pure Water Machines

1. **Pre-Filtration Systems**: These systems remove larger particles and sediments before water enters the main purification stage.

2. **Membrane Technology**: Reverse osmosis membranes are crucial for removing dissolved solids and microorganisms.

3. **Ion Exchange Resins**: Used for deionization, these resins remove ions from water, further enhancing purity.

4. **UV Treatment**: Ultraviolet light can be used to sterilize water, eliminating any remaining pathogens.

The Technology Behind Ultra Pure Water Systems

The technology employed in ultra pure water machines is continually evolving, driven by the demand for higher purity standards and more efficient processes.

Advanced Filtration Techniques

**Granular Activated Carbon (GAC)**: This filtration method is effective for removing chlorine and organic compounds. GAC filters improve the taste and odor of water.

**Reverse Osmosis (RO)**: RO is a key technology in ultra pure water systems. It uses pressure to force water through a semipermeable membrane, effectively removing a wide range of contaminants.

**Electrodeionization (EDI)**: EDI combines ion exchange and electrochemical processes to achieve ultra-pure water without the need for chemical regeneration.

Automation and Smart Technologies

Modern ultra pure water machines often incorporate smart technologies for monitoring and control. These systems can track water quality metrics in real-time, ensuring that purity standards are consistently met. Automation reduces human error and enhances operational efficiency.

Environmental Benefits of Ultra Pure Water Machines

The adoption of ultra pure water machines contributes significantly to environmental sustainability in several ways:

1. Reduced Water Wastage

Traditional water purification methods often result in significant water wastage. Ultra pure water systems are designed to minimize this by optimizing water recovery rates, thereby conserving this precious resource.

2. Lower Energy Consumption

Many ultra pure water machines are engineered for energy efficiency. By employing advanced technologies such as energy recovery devices, these systems significantly reduce the energy required for water purification processes.

3. Decreased Chemical Use

Conventional water treatment methods frequently involve the use of harsh chemicals. In contrast, ultra pure water systems can often achieve the desired level of purity without relying on chemical additives, leading to less environmental pollution.

4. Supporting Renewable Energy Initiatives

The integration of ultra pure water machines with renewable energy sources, such as solar or wind power, can further enhance their sustainability. These systems can operate off-grid or in combination with local renewable energy projects, reducing reliance on fossil fuels.

Industrial Applications of Ultra Pure Water Machines

Ultra pure water machines are indispensable in various industries, each with unique demands for water purity.

1. Pharmaceutical Industry

In the pharmaceutical sector, the quality of water used in drug formulation is critical. Ultra pure water machines ensure that the water meets the stringent quality standards required for the production of medications, thus safeguarding public health.

2. Semiconductor Manufacturing

The semiconductor industry relies on ultra pure water for cleaning and processing materials. Even minute impurities can lead to defects in electronic components, making ultra pure water essential for maintaining product integrity.

3. Laboratory Research

Research laboratories require ultra pure water for experiments to ensure accuracy and reliability. Contaminated water can lead to erroneous results, making the use of ultra pure water machines a necessity for scientific research.

4. Food and Beverage Industry

In the food and beverage sector, water quality directly impacts product safety and flavor. Ultra pure water machines help manufacturers comply with health regulations and produce high-quality products.

Challenges in Implementing Ultra Pure Water Systems

While the benefits of ultra pure water machines are significant, several challenges can arise during implementation.

1. High Initial Investment

The cost of acquiring and installing ultra pure water systems can be substantial. Companies must consider the return on investment over time, particularly in industries where high water purity is non-negotiable.

2. Maintenance and Operation

Maintaining ultra pure water systems requires expertise and regular monitoring. Organizations must invest in training personnel to ensure the systems operate efficiently and effectively.

3. Technological Adaptation

As technologies evolve, older systems may become outdated or less efficient. Staying abreast of advancements in ultra pure water technology is essential for maintaining operational excellence.

Conclusion: A Pathway to a Sustainable Future

The role of ultra pure water machines in promoting environmental sustainability cannot be overstated. As industries increasingly recognize the importance of high-quality water in their processes, the demand for ultra pure water systems will only grow. By efficiently purifying water, reducing waste, and minimizing energy consumption, these machines are crucial for fostering a sustainable future. Investing in ultra pure water technology is not just a step toward compliance; it is a commitment to environmental stewardship, public health, and responsible resource management.

FAQs

1. What is ultra pure water?

Ultra pure water is water that has been treated to remove nearly all contaminants, including ions, organic materials, and microorganisms, making it suitable for sensitive applications.

2. How do ultra pure water machines work?

Ultra pure water machines use advanced filtration techniques such as reverse osmosis, deionization, and UV treatment to ensure the highest levels of water purity.

3. Why is ultra pure water important in the pharmaceutical industry?

In the pharmaceutical industry, ultra pure water is essential for drug formulation, as impurities can compromise product safety and efficacy.

4. Are ultra pure water systems energy-efficient?

Many ultra pure water systems are designed for energy efficiency, employing technologies that reduce energy consumption during the purification process.

5. What industries benefit from ultra pure water machines?

Industries such as pharmaceuticals, semiconductor manufacturing, laboratory research, and food and beverage production all benefit from ultra pure water machines, as they require high water purity for their processes.

RELATED NEWS