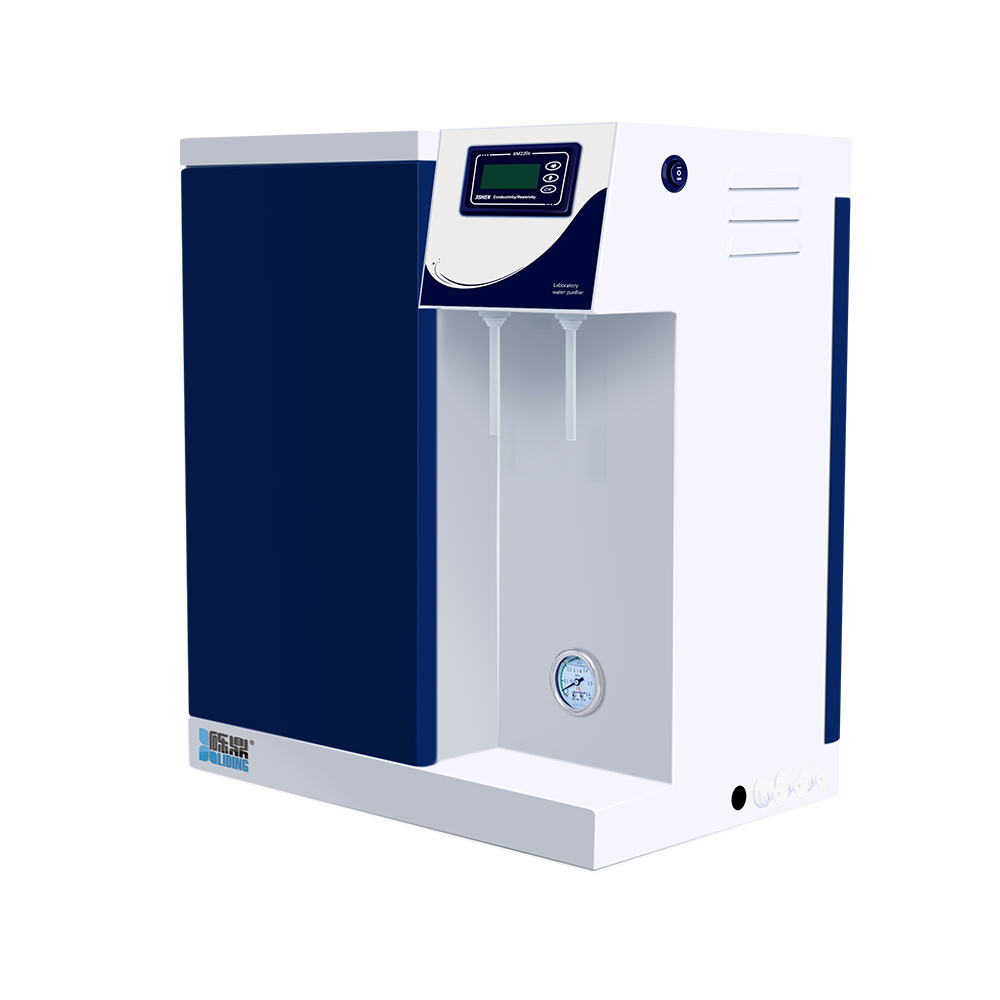

Unlocking the Benefits of Ultra Pure Water Purification Systems in Industrial Applications

Time:

Jul 10,2025

Ultra pure water purification systems are pivotal in various industrial applications where water quality is paramount. These systems are engineered to deliver exceptionally high purity levels, often achieving a resistivity greater than 18.2 MΩ·cm, which is crucial for processes that require contaminant-free water.

The purification process typically involves multiple stages, including pretreatment, reverse osmosis, and deionization. Initially, pretreatment may include microfiltration or ultrafiltration to eliminate larger particulates and microorganisms, safeguarding the subsequent purification steps. Reverse osmosis (RO) is then employed to remove dissolved salts and organic compounds, leveraging semi-permeable membranes that allow only water molecules to pass through while rejecting contaminants. Finally, deionization utilizes ion exchange resins to further purify the water by removing remaining ionic impurities.

One of the primary advantages of ultra pure water purification systems is their ability to enhance the reliability and efficiency of industrial processes. For example, in semiconductor manufacturing, the presence of even trace contaminants can lead to defects in integrated circuits, resulting in significant financial losses. By deploying ultra pure water systems, manufacturers can ensure that the water used in rinse processes is devoid of contaminants, thus maintaining the integrity of their products.

Moreover, these systems contribute to energy efficiency and operational sustainability. By implementing advanced technologies, industries can reduce waste and minimize the environmental impact associated with water usage. This is particularly crucial in sectors where water scarcity is a growing concern.

Another critical aspect of ultra pure water purification systems is their role in regulatory compliance. Industries such as pharmaceuticals, biotechnology, and microelectronics are subject to stringent quality standards set by regulatory bodies. Ultra pure water meets these standards, ensuring that production processes adhere to the necessary guidelines for safety and quality.

In conclusion, investing in ultra pure water purification systems is not merely a matter of achieving high water quality; it is about enhancing operational efficiency, safeguarding product integrity, and ensuring compliance with industry regulations. As industries continue to prioritize sustainability and quality assurance, the need for these advanced purification systems will only grow. Ensuring that your operations are equipped with the right technology can ultimately lead to improved performance and a competitive edge in the market.

The purification process typically involves multiple stages, including pretreatment, reverse osmosis, and deionization. Initially, pretreatment may include microfiltration or ultrafiltration to eliminate larger particulates and microorganisms, safeguarding the subsequent purification steps. Reverse osmosis (RO) is then employed to remove dissolved salts and organic compounds, leveraging semi-permeable membranes that allow only water molecules to pass through while rejecting contaminants. Finally, deionization utilizes ion exchange resins to further purify the water by removing remaining ionic impurities.

One of the primary advantages of ultra pure water purification systems is their ability to enhance the reliability and efficiency of industrial processes. For example, in semiconductor manufacturing, the presence of even trace contaminants can lead to defects in integrated circuits, resulting in significant financial losses. By deploying ultra pure water systems, manufacturers can ensure that the water used in rinse processes is devoid of contaminants, thus maintaining the integrity of their products.

Moreover, these systems contribute to energy efficiency and operational sustainability. By implementing advanced technologies, industries can reduce waste and minimize the environmental impact associated with water usage. This is particularly crucial in sectors where water scarcity is a growing concern.

Another critical aspect of ultra pure water purification systems is their role in regulatory compliance. Industries such as pharmaceuticals, biotechnology, and microelectronics are subject to stringent quality standards set by regulatory bodies. Ultra pure water meets these standards, ensuring that production processes adhere to the necessary guidelines for safety and quality.

In conclusion, investing in ultra pure water purification systems is not merely a matter of achieving high water quality; it is about enhancing operational efficiency, safeguarding product integrity, and ensuring compliance with industry regulations. As industries continue to prioritize sustainability and quality assurance, the need for these advanced purification systems will only grow. Ensuring that your operations are equipped with the right technology can ultimately lead to improved performance and a competitive edge in the market.

RELATED NEWS