Understanding Ultrapure Water Purification Systems: Essential Insights for Industrial Applications

Time:

Oct 08,2025

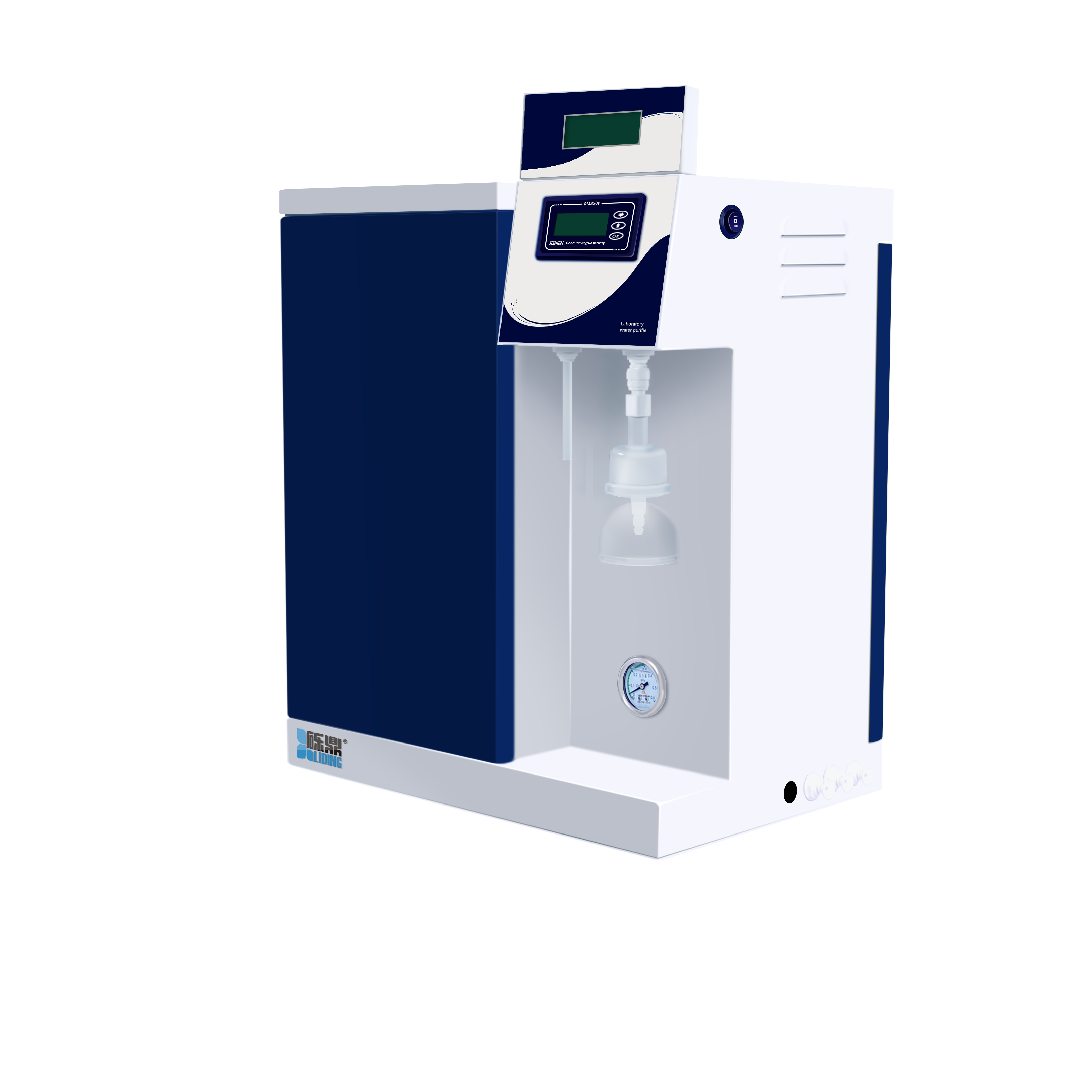

Ultrapure water purification systems are critical components in numerous industrial processes, especially in industries such as pharmaceuticals, electronics, and biotechnology. The demand for high-quality water in these sectors necessitates advanced purification technologies that ensure the removal of impurities to achieve the highest levels of water purity.

At its core, an ultrapure water purification system is designed to eliminate contaminants that are typically found in standard water supplies. These systems go beyond conventional water treatment methods, utilizing a combination of techniques such as reverse osmosis, deionization, and distillation. By leveraging these technologies, ultrapure water systems can achieve conductivity levels of less than 0.055 microsiemens/cm, which is essential for processes where even trace amounts of impurities can affect product quality and operational efficiency.

One of the primary benefits of ultrapure water purification systems is their ability to cater to specific application requirements. In the semiconductor industry, for example, ultrapure water is crucial for cleaning and rinsing wafers, as even the slightest contamination can lead to defects in the final product. Similarly, in pharmaceutical manufacturing, the use of ultrapure water is vital for formulating drugs and ensuring compliance with stringent regulatory standards.

Moreover, ultrapure water systems contribute to sustainability efforts by minimizing waste and optimizing resource usage. Many modern systems are designed with energy-efficient processes and minimal chemical use, aligning with the industry's increasing focus on reducing environmental impact. By investing in these advanced purification systems, companies can improve their overall operational efficiency while adhering to environmental regulations.

Regular maintenance and monitoring of ultrapure water purification systems are essential to ensure their continued performance and reliability. This includes routine checks of the filtration media, regular replacement of membranes, and continuous monitoring of water quality parameters. By establishing a proactive maintenance regimen, industries can avoid production downtime and mitigate the risks associated with water quality fluctuations.

In conclusion, ultrapure water purification systems play a pivotal role in various industrial applications, where the need for high-quality water is paramount. Understanding the principles behind these systems, their benefits, and the importance of maintenance can empower businesses to make informed decisions regarding water treatment solutions. By prioritizing water purity, industries can enhance product quality, streamline processes, and contribute to sustainable practices that benefit both the economy and the environment.

At its core, an ultrapure water purification system is designed to eliminate contaminants that are typically found in standard water supplies. These systems go beyond conventional water treatment methods, utilizing a combination of techniques such as reverse osmosis, deionization, and distillation. By leveraging these technologies, ultrapure water systems can achieve conductivity levels of less than 0.055 microsiemens/cm, which is essential for processes where even trace amounts of impurities can affect product quality and operational efficiency.

One of the primary benefits of ultrapure water purification systems is their ability to cater to specific application requirements. In the semiconductor industry, for example, ultrapure water is crucial for cleaning and rinsing wafers, as even the slightest contamination can lead to defects in the final product. Similarly, in pharmaceutical manufacturing, the use of ultrapure water is vital for formulating drugs and ensuring compliance with stringent regulatory standards.

Moreover, ultrapure water systems contribute to sustainability efforts by minimizing waste and optimizing resource usage. Many modern systems are designed with energy-efficient processes and minimal chemical use, aligning with the industry's increasing focus on reducing environmental impact. By investing in these advanced purification systems, companies can improve their overall operational efficiency while adhering to environmental regulations.

Regular maintenance and monitoring of ultrapure water purification systems are essential to ensure their continued performance and reliability. This includes routine checks of the filtration media, regular replacement of membranes, and continuous monitoring of water quality parameters. By establishing a proactive maintenance regimen, industries can avoid production downtime and mitigate the risks associated with water quality fluctuations.

In conclusion, ultrapure water purification systems play a pivotal role in various industrial applications, where the need for high-quality water is paramount. Understanding the principles behind these systems, their benefits, and the importance of maintenance can empower businesses to make informed decisions regarding water treatment solutions. By prioritizing water purity, industries can enhance product quality, streamline processes, and contribute to sustainable practices that benefit both the economy and the environment.

RELATED NEWS