How Ultra Pure Water Equipment Can Significantly Reduce Operational Costs

Time:

Oct 05,2025

How Ultra Pure Water Equipment Can Significantly Reduce Operational Costs

Table of Contents

- 1. Introduction to Ultra Pure Water Equipment

- 2. Understanding Ultra Pure Water: What It Is and Why It Matters

- 3. The Relationship Between Ultra Pure Water and Operational Costs

- 4. Key Components of Ultra Pure Water Treatment Systems

- 5. Benefits of Implementing Ultra Pure Water Equipment

- 6. Case Studies: Successful Cost Reductions with Ultra Pure Water Systems

- 7. Best Practices for Implementing Ultra Pure Water Equipment

- 8. Future Trends in Ultra Pure Water Treatment Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Ultra Pure Water Equipment

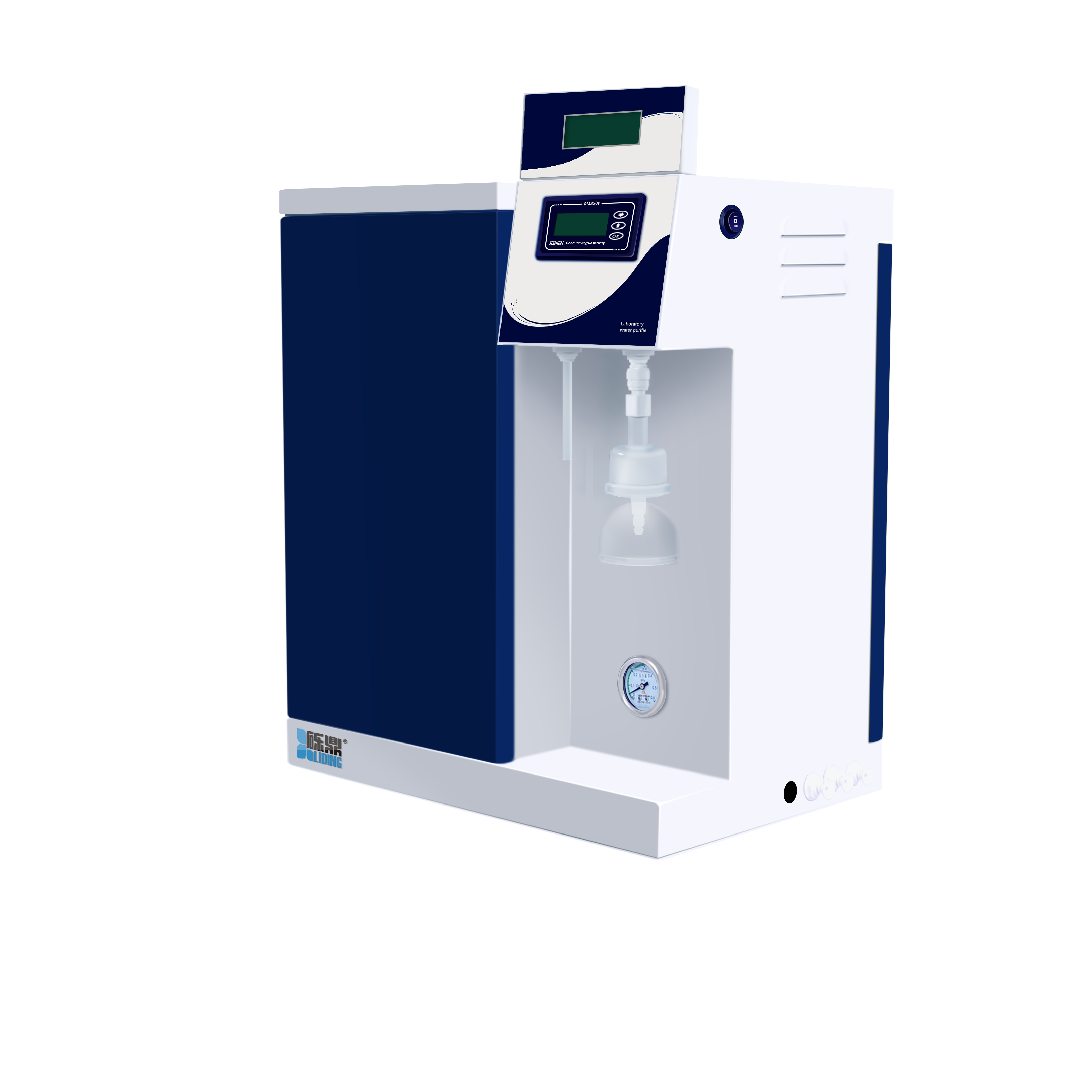

In an era where operational efficiency and cost management play a pivotal role in business success, the quest for optimal solutions is more critical than ever. Enter **ultra pure water equipment**, a game-changing technology that not only enhances the quality of water used in industrial processes but also significantly reduces operational costs. By investing in these systems, companies can streamline processes, ensure regulatory compliance, and achieve sustainability goals—all crucial factors in today’s competitive landscape.

2. Understanding Ultra Pure Water: What It Is and Why It Matters

**Ultra pure water (UPW)** is water that has been treated to remove nearly all impurities, including dissolved salts, organic molecules, and microorganisms. The resulting water is of such high purity that it meets stringent standards required for various applications, particularly in industries such as semiconductor manufacturing, pharmaceuticals, and power generation.

The significance of ultra pure water cannot be overstated. In many sectors, the quality of water directly impacts product quality, equipment lifespan, and operational efficiency. By utilizing UPW, businesses can ensure that their processes function at optimal levels, thereby reducing waste and costs associated with downtime, equipment repair, and rework.

3. The Relationship Between Ultra Pure Water and Operational Costs

Understanding how ultra pure water equipment can help reduce operational costs involves examining several key factors. These include:

3.1 Reduced Downtime

One of the most significant ways UPW contributes to cost savings is through reduced downtime in production processes. Contaminated water can lead to equipment failure, maintenance issues, and production halts. By ensuring that only ultra pure water is used, companies can minimize these risks, leading to fewer interruptions and increased productivity.

3.2 Decreased Maintenance Costs

Equipment that operates with high-quality water tends to have a longer lifespan. By combating scaling, corrosion, and fouling, ultra pure water systems reduce the frequency and costs associated with maintenance and repairs. This not only saves money but also enhances overall equipment efficiency.

3.3 Enhanced Product Quality

For industries where product quality is paramount, such as pharmaceuticals and electronics, the use of ultra pure water can lead to fewer defects and higher-quality outputs. This translates to lower costs in quality control, rework, and returns, ultimately improving profit margins.

3.4 Compliance and Risk Management

Many industries are subject to strict regulatory standards regarding water quality. Implementing ultra pure water systems can help ensure compliance, reducing the risk of fines and penalties. Moreover, by minimizing the possibility of contamination, businesses can mitigate financial risks associated with product recalls and liability claims.

4. Key Components of Ultra Pure Water Treatment Systems

To fully understand the capabilities of ultra pure water systems, it's essential to know their key components. These systems typically include:

4.1 Pre-Treatment Systems

These systems remove larger particles and contaminants from raw water before it undergoes further purification. Techniques may include filtration, sedimentation, or ion exchange.

4.2 Reverse Osmosis (RO) Units

RO is a critical process in ultra pure water production. This technology uses semi-permeable membranes to remove dissolved solids and contaminants, producing high-purity water suitable for industrial applications.

4.3 Electrodeionization (EDI)

EDI is often used in conjunction with RO to achieve ultra-pure water quality. This process uses electrical current to remove ionized species from water, ensuring minimal contaminant levels.

4.4 Ultraviolet (UV) Disinfection Systems

To eliminate bacteria and viruses, UV disinfection systems are employed. This non-chemical method ensures that the water remains free from microbial contamination, vital for sensitive applications.

4.5 Final Polishing Units

Final polishing units, such as mixed-bed ion exchange systems, are used to ensure that the water meets the highest purity standards required for specific industrial processes.

5. Benefits of Implementing Ultra Pure Water Equipment

Implementing ultra pure water equipment offers a plethora of benefits, enhancing both operational efficiency and cost savings. Some of the most notable advantages include:

5.1 Increased Efficiency

With ultra pure water systems, industries can operate at higher efficiencies. Cleaner water results in less wear and tear on machinery, reducing energy consumption and operational costs.

5.2 Environmental Sustainability

Utilizing UPW systems also aligns with sustainability initiatives. By reducing wastewater generation and improving water recycling, businesses can lower their environmental impact while potentially qualifying for green certifications.

5.3 Scalability and Flexibility

As industries expand, the demand for ultra pure water often increases. Modern UPW systems are designed with scalability in mind, allowing businesses to easily adjust capacity according to their needs without significant additional investments.

5.4 Improved Safety

By using ultra pure water, companies can ensure a safer working environment. This is particularly crucial in industries where contaminants can pose health risks to workers or consumers.

6. Case Studies: Successful Cost Reductions with Ultra Pure Water Systems

Examining real-world examples can shed light on the effectiveness of ultra pure water equipment in reducing operational costs.

6.1 Semiconductor Manufacturing

In the semiconductor industry, a major manufacturer implemented an ultra pure water system and recorded a **30% reduction in operational costs** within the first year. The enhanced water quality significantly decreased equipment downtime and maintenance costs, resulting in increased production rates and profitability.

6.2 Pharmaceutical Production

A pharmaceutical company struggled with product quality issues due to water contamination. After installing a state-of-the-art UPW system, they experienced a **40% decrease in defects**, leading to higher customer satisfaction and reduced costs related to rework and recalls.

7. Best Practices for Implementing Ultra Pure Water Equipment

To maximize the benefits of ultra pure water systems, businesses should consider the following best practices:

7.1 Conduct a Thorough Needs Assessment

Before investing in UPW technology, it's crucial to assess the specific needs of your industry and processes. Understanding the required water quality and volume will guide equipment selection and ensure optimal performance.

7.2 Partner with Reliable Suppliers

Choose reputable suppliers with a proven track record in ultra pure water systems. Collaborating with experienced partners ensures you receive quality equipment and support throughout the implementation process.

7.3 Regular Maintenance and Monitoring

Implement a regular maintenance schedule to ensure the UPW system operates at peak efficiency. Continuous monitoring of water quality can help identify potential issues before they escalate, ensuring consistent performance.

8. Future Trends in Ultra Pure Water Treatment Technology

As technology evolves, so does the landscape of ultra pure water treatment. Several trends are emerging that promise to further enhance operational efficiency and cost savings:

8.1 Automation and Smart Technology

The integration of smart technology into UPW systems allows for real-time monitoring and automated adjustments. This leads to improved efficiency and reduced human error, resulting in significant cost savings over time.

8.2 Advanced Membrane Technologies

Innovations in membrane technology are enhancing the performance of reverse osmosis and other filtration systems. These advancements will likely lead to increased efficiency and lower costs associated with energy and maintenance.

8.3 Increased Focus on Sustainability

With growing environmental awareness, the demand for sustainable water treatment solutions is rising. Future ultra pure water systems will likely emphasize resource recovery and reduced environmental impact, aligning with global sustainability goals.

9. Frequently Asked Questions

9.1 What industries benefit from ultra pure water equipment?

Industries such as semiconductor manufacturing, pharmaceuticals, power generation, and food & beverage greatly benefit from ultra pure water systems due to the high purity standards required for their processes.

9.2 How much can ultra pure water systems reduce operational costs?

While cost reductions vary depending on the specific application and existing systems, businesses can expect savings ranging from **20% to 40%** in operational costs by implementing ultra pure water equipment.

9.3 What is the maintenance required for ultra pure water systems?

Regular maintenance includes monitoring water quality, replacing filters and membranes as needed, and servicing equipment to ensure optimal performance. A well-maintained system can provide reliable service for many years.

9.4 Can ultra pure water systems be customized for specific needs?

Yes, ultra pure water systems can be tailored to meet the specific needs of different industries and applications, including adjusting capacity and incorporating various treatment technologies as necessary.

9.5 Are there any regulatory standards for ultra pure water?

Yes, various industries have specific regulatory standards for water quality. Meeting these standards is crucial for compliance and ensuring product safety and quality.

10. Conclusion

In today's competitive industrial landscape, embracing technology that enhances operational efficiency and reduces costs is imperative. **Ultra pure water equipment** stands at the forefront of this transformation, offering clear financial benefits while ensuring product quality and regulatory compliance. By investing in ultra pure water systems, businesses can achieve significant cost savings, enhance their sustainability efforts, and secure a competitive edge in their respective markets. The future of ultra pure water technology promises even greater innovations, reinforcing its importance in the ongoing evolution of industrial processes.