Understanding Ultra Pure Water Machines: Essential Equipment for Industrial Water Treatment

Time:

Jul 22,2025

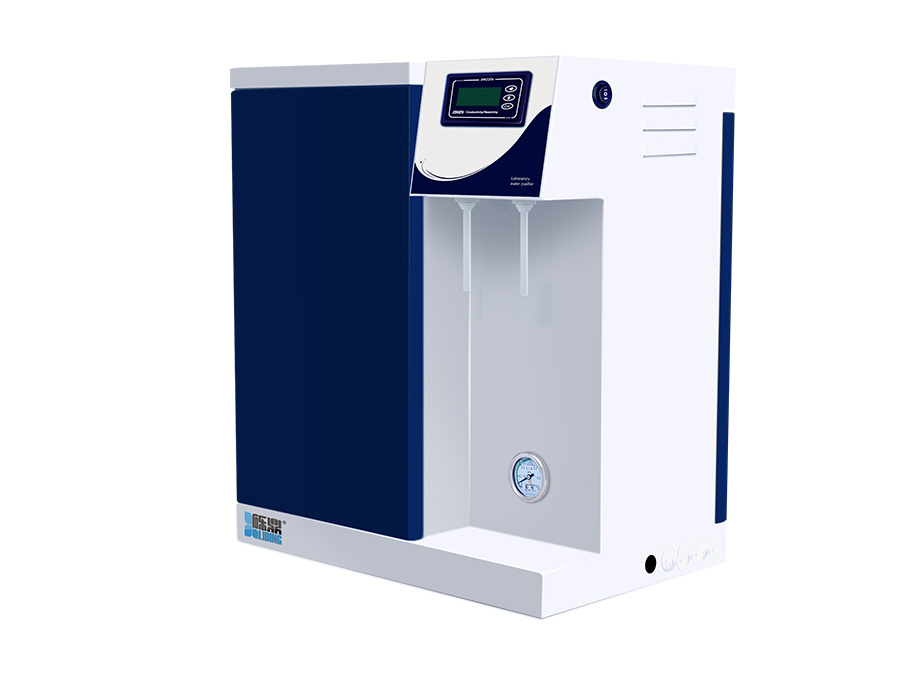

Ultra pure water machines are specialized systems designed to produce water with extremely low levels of impurities, making them essential for industries such as pharmaceuticals, semiconductors, and laboratories. The purity level of the water generated by these machines typically meets or exceeds the stringent standards set by regulatory bodies, ensuring that the end product is free from contaminants that could compromise quality.

The operation of an ultra pure water machine involves several advanced water treatment processes. Typically, these systems integrate multiple technologies, including reverse osmosis (RO), deionization (DI), and ultrafiltration (UF). Reverse osmosis is a critical step that utilizes semi-permeable membranes to remove dissolved solids, organic compounds, and other impurities present in the feed water. This process is followed by deionization, which uses ion exchange resins to eliminate remaining ions and achieve the desired conductivity levels.

Maintaining the efficiency and effectiveness of ultra pure water machines requires regular monitoring and maintenance. Key performance parameters such as flow rate, conductivity, and total organic carbon (TOC) levels should be routinely evaluated. Any deviations from the established benchmarks may indicate a need for system adjustments or component replacements. Implementing a proactive maintenance schedule helps ensure optimal operation, prolonging the lifespan of the equipment and safeguarding the quality of the produced water.

Furthermore, the design of ultra pure water machines often incorporates advanced monitoring systems that allow real-time tracking of water quality. Many modern systems come equipped with automated features, including alarms and alerts, to notify operators of any irregularities in water production or quality. This automation not only enhances operational efficiency but also reduces the risk of human error.

In conclusion, ultra pure water machines are invaluable assets in the realm of industrial water treatment, designed to meet the high standards required for various critical applications. By understanding their operation, maintenance requirements, and the technologies involved, professionals can better appreciate the significance of these systems in ensuring water purity. As industries continue to evolve, the demand for ultra pure water machines will likely grow, emphasizing the importance of staying informed about the latest advancements and best practices in water treatment technologies.

The operation of an ultra pure water machine involves several advanced water treatment processes. Typically, these systems integrate multiple technologies, including reverse osmosis (RO), deionization (DI), and ultrafiltration (UF). Reverse osmosis is a critical step that utilizes semi-permeable membranes to remove dissolved solids, organic compounds, and other impurities present in the feed water. This process is followed by deionization, which uses ion exchange resins to eliminate remaining ions and achieve the desired conductivity levels.

Maintaining the efficiency and effectiveness of ultra pure water machines requires regular monitoring and maintenance. Key performance parameters such as flow rate, conductivity, and total organic carbon (TOC) levels should be routinely evaluated. Any deviations from the established benchmarks may indicate a need for system adjustments or component replacements. Implementing a proactive maintenance schedule helps ensure optimal operation, prolonging the lifespan of the equipment and safeguarding the quality of the produced water.

Furthermore, the design of ultra pure water machines often incorporates advanced monitoring systems that allow real-time tracking of water quality. Many modern systems come equipped with automated features, including alarms and alerts, to notify operators of any irregularities in water production or quality. This automation not only enhances operational efficiency but also reduces the risk of human error.

In conclusion, ultra pure water machines are invaluable assets in the realm of industrial water treatment, designed to meet the high standards required for various critical applications. By understanding their operation, maintenance requirements, and the technologies involved, professionals can better appreciate the significance of these systems in ensuring water purity. As industries continue to evolve, the demand for ultra pure water machines will likely grow, emphasizing the importance of staying informed about the latest advancements and best practices in water treatment technologies.

RELATED NEWS