Comprehensive Insights into Ultrapure Water Systems for Laboratory Applications

Time:

Jul 20,2025

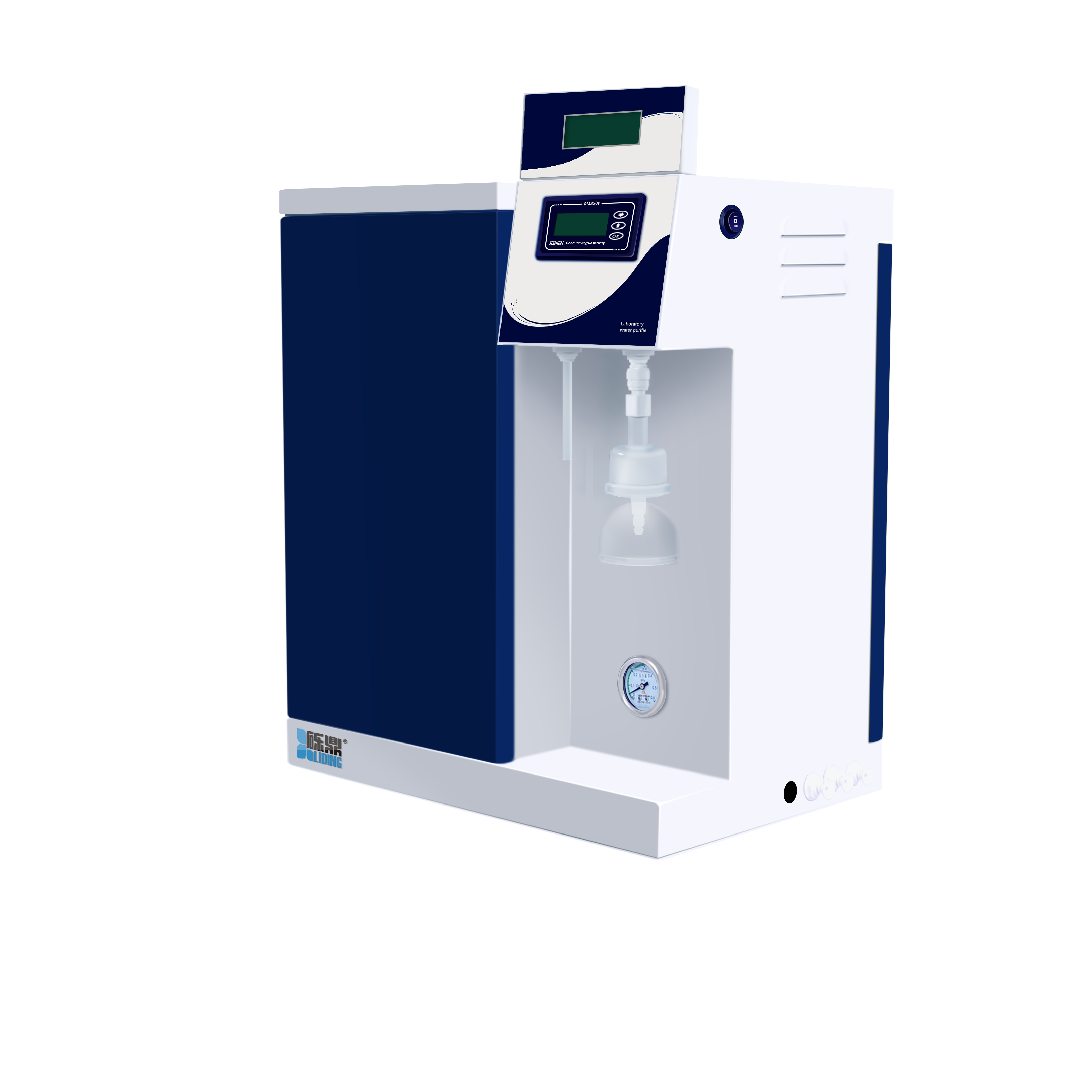

Ultrapure water systems are essential components in laboratory settings, particularly for applications requiring the highest levels of water purity, such as in pharmaceuticals, electronics, and analytical chemistry. The primary objective of these systems is to produce water that meets stringent purity standards, often defined by low levels of contaminants, including ions, organic compounds, and microorganisms.

One of the key technologies employed in ultrapure water systems is reverse osmosis (RO), which effectively reduces the concentration of dissolved salts and other impurities in the water. Following reverse osmosis, additional purification processes are typically utilized, such as deionization (DI) and ultraviolet (UV) sterilization. Deionization removes ionic contaminants, while UV treatment targets microbiological impurities, ensuring that the resultant ultrapure water is suitable for even the most sensitive laboratory applications.

Another significant aspect of ultrapure water systems is their ability to integrate various filtration methods. For instance, a multi-barrier approach may involve utilizing activated carbon filters to remove organic compounds and chlorine, followed by membrane filtration techniques to ensure further reduction of particulates. This layered strategy enhances the overall effectiveness of the system, creating a robust solution for achieving the desired water quality.

When considering an ultrapure water system for a laboratory, several factors must be taken into account. The specific requirements of the application dictate the necessary purification levels and system configurations. For instance, laboratories engaged in molecular biology may require different purity levels compared to those involved in materials science. Therefore, understanding the specific applications and their associated purity requirements is critical in selecting the right system.

Additionally, maintenance and monitoring are crucial for the longevity and performance of ultrapure water systems. Regular checks on the system's components, such as filters and membranes, are necessary to prevent any degradation in water quality. Implementing a routine maintenance schedule can significantly enhance the reliability of the system and ensure consistent water purity.

Moreover, advancements in technology are leading to more efficient and compact ultrapure water systems. These innovations are designed to minimize water waste and energy consumption while maximizing performance. As laboratories continue to evolve and expand their capabilities, the demand for high-quality ultrapure water is expected to grow, making it imperative for professionals in the industry to stay informed about the latest developments in this field.

In conclusion, ultrapure water systems play a pivotal role in laboratory operations, necessitating a clear understanding of their functionalities, maintenance, and application-specific requirements. By leveraging advanced purification technologies and adhering to best practices, laboratories can ensure the availability of high-quality water, supporting their research and development activities effectively.

One of the key technologies employed in ultrapure water systems is reverse osmosis (RO), which effectively reduces the concentration of dissolved salts and other impurities in the water. Following reverse osmosis, additional purification processes are typically utilized, such as deionization (DI) and ultraviolet (UV) sterilization. Deionization removes ionic contaminants, while UV treatment targets microbiological impurities, ensuring that the resultant ultrapure water is suitable for even the most sensitive laboratory applications.

Another significant aspect of ultrapure water systems is their ability to integrate various filtration methods. For instance, a multi-barrier approach may involve utilizing activated carbon filters to remove organic compounds and chlorine, followed by membrane filtration techniques to ensure further reduction of particulates. This layered strategy enhances the overall effectiveness of the system, creating a robust solution for achieving the desired water quality.

When considering an ultrapure water system for a laboratory, several factors must be taken into account. The specific requirements of the application dictate the necessary purification levels and system configurations. For instance, laboratories engaged in molecular biology may require different purity levels compared to those involved in materials science. Therefore, understanding the specific applications and their associated purity requirements is critical in selecting the right system.

Additionally, maintenance and monitoring are crucial for the longevity and performance of ultrapure water systems. Regular checks on the system's components, such as filters and membranes, are necessary to prevent any degradation in water quality. Implementing a routine maintenance schedule can significantly enhance the reliability of the system and ensure consistent water purity.

Moreover, advancements in technology are leading to more efficient and compact ultrapure water systems. These innovations are designed to minimize water waste and energy consumption while maximizing performance. As laboratories continue to evolve and expand their capabilities, the demand for high-quality ultrapure water is expected to grow, making it imperative for professionals in the industry to stay informed about the latest developments in this field.

In conclusion, ultrapure water systems play a pivotal role in laboratory operations, necessitating a clear understanding of their functionalities, maintenance, and application-specific requirements. By leveraging advanced purification technologies and adhering to best practices, laboratories can ensure the availability of high-quality water, supporting their research and development activities effectively.

RELATED NEWS