The Comprehensive Guide to Ultra Purified Water Systems for Industrial Applications

Time:

Jun 22,2025

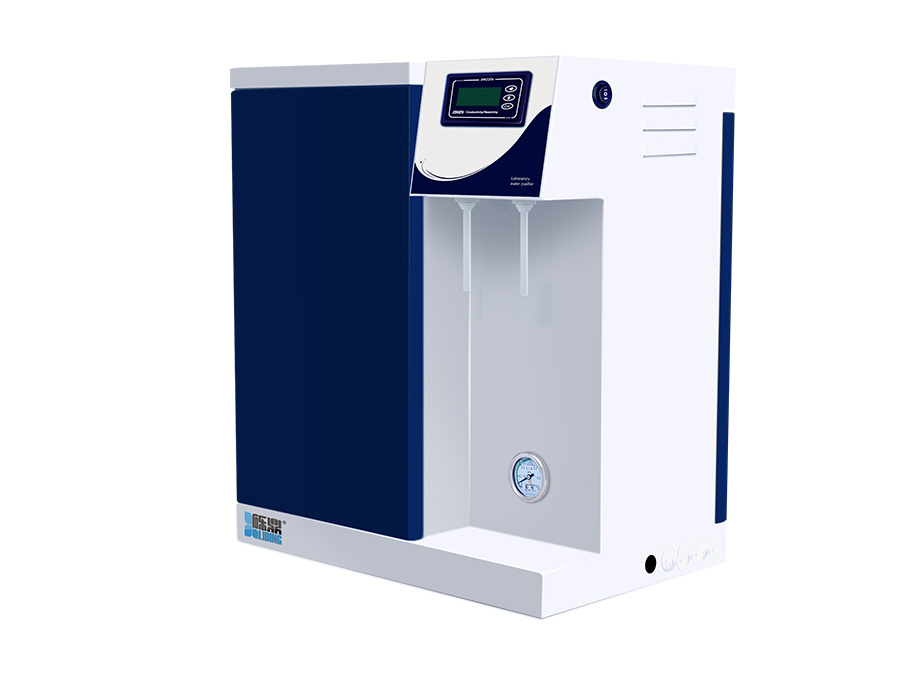

Ultra purified water systems are essential components in various industrial applications where water quality is paramount. These systems are designed to reduce impurities to extremely low levels, ensuring that the water meets stringent quality standards necessary for various processes. This article delves into the technology behind ultra purified water systems, their benefits, and their applications in industrial settings.

The foundation of ultra purified water systems is advanced filtration and purification technologies. These systems typically incorporate multiple treatment processes, including reverse osmosis, deionization, and ultraviolet (UV) light sterilization. Each stage is critical in removing contaminants such as bacteria, viruses, heavy metals, and dissolved solids. By employing multiple purification methods, ultra purified water systems can achieve a conductivity level of less than 1 microsiemens/cm, making the water suitable for sensitive applications.

One of the primary advantages of ultra purified water is its ability to enhance the performance and efficiency of industrial processes. In sectors such as pharmaceuticals, electronics, and food and beverage manufacturing, the quality of water directly impacts product quality and compliance with regulatory standards. For instance, in pharmaceutical production, ultra purified water is often used as an ingredient in drug formulations or as a cleaning agent for equipment. Its high purity ensures that there are no unwanted residues that could affect the efficacy of medications.

Moreover, ultra purified water systems contribute to sustainability efforts in various industries. By ensuring that water is treated and reused effectively, companies can significantly reduce their water consumption and waste. For instance, in a semiconductor manufacturing facility, the use of ultra purified water aids in the cooling and cleaning processes, minimizing the need for additional water sources.

The installation and maintenance of ultra purified water systems require careful consideration of several factors. First, the selection of appropriate equipment based on the specific water quality requirements is crucial. Regular monitoring and maintenance are also essential to ensure that the system operates at peak efficiency. This includes periodic checks of filter integrity, cleaning of membranes, and calibration of UV lamps. By following best practices in maintenance, industries can extend the lifespan of their water treatment systems and prevent potential downtime.

In conclusion, ultra purified water systems play a vital role in modern industrial applications. By employing a combination of advanced purification technologies, these systems ensure that water quality meets the rigorous standards demanded by various sectors. The benefits of ultra purified water extend beyond compliance; they enhance overall operational efficiency and contribute to sustainability goals. As industries continue to evolve, the importance of high-quality water treatment will only grow, making ultra purified water systems a critical investment for the future.

The foundation of ultra purified water systems is advanced filtration and purification technologies. These systems typically incorporate multiple treatment processes, including reverse osmosis, deionization, and ultraviolet (UV) light sterilization. Each stage is critical in removing contaminants such as bacteria, viruses, heavy metals, and dissolved solids. By employing multiple purification methods, ultra purified water systems can achieve a conductivity level of less than 1 microsiemens/cm, making the water suitable for sensitive applications.

One of the primary advantages of ultra purified water is its ability to enhance the performance and efficiency of industrial processes. In sectors such as pharmaceuticals, electronics, and food and beverage manufacturing, the quality of water directly impacts product quality and compliance with regulatory standards. For instance, in pharmaceutical production, ultra purified water is often used as an ingredient in drug formulations or as a cleaning agent for equipment. Its high purity ensures that there are no unwanted residues that could affect the efficacy of medications.

Moreover, ultra purified water systems contribute to sustainability efforts in various industries. By ensuring that water is treated and reused effectively, companies can significantly reduce their water consumption and waste. For instance, in a semiconductor manufacturing facility, the use of ultra purified water aids in the cooling and cleaning processes, minimizing the need for additional water sources.

The installation and maintenance of ultra purified water systems require careful consideration of several factors. First, the selection of appropriate equipment based on the specific water quality requirements is crucial. Regular monitoring and maintenance are also essential to ensure that the system operates at peak efficiency. This includes periodic checks of filter integrity, cleaning of membranes, and calibration of UV lamps. By following best practices in maintenance, industries can extend the lifespan of their water treatment systems and prevent potential downtime.

In conclusion, ultra purified water systems play a vital role in modern industrial applications. By employing a combination of advanced purification technologies, these systems ensure that water quality meets the rigorous standards demanded by various sectors. The benefits of ultra purified water extend beyond compliance; they enhance overall operational efficiency and contribute to sustainability goals. As industries continue to evolve, the importance of high-quality water treatment will only grow, making ultra purified water systems a critical investment for the future.

RELATED NEWS