The Essential Guide to Ultra Pure Water Purification Systems

Time:

Jun 18,2025

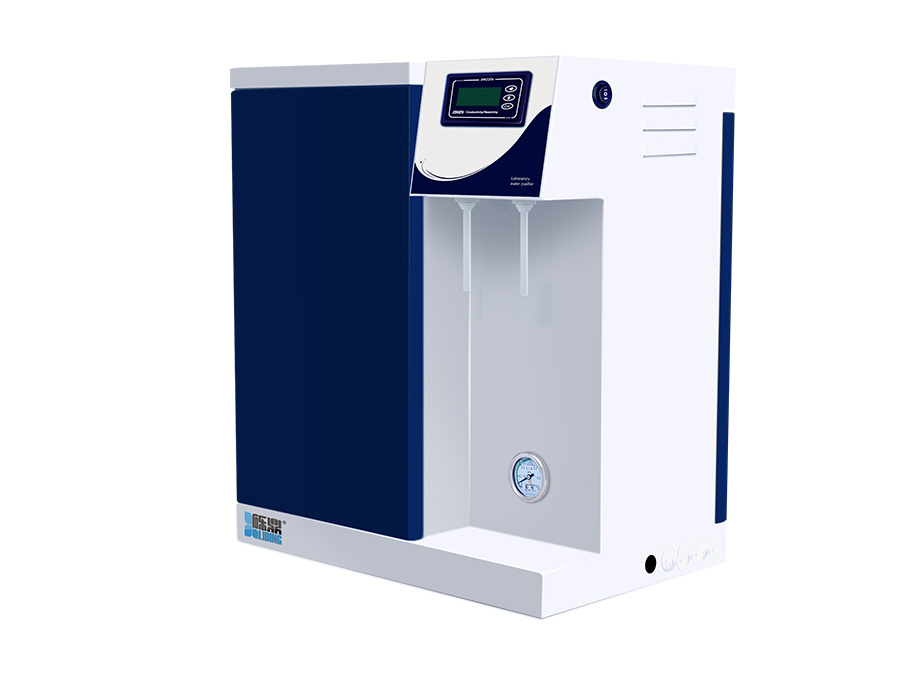

Ultra pure water purification systems are designed to produce water with extremely low levels of contaminants, making them essential in various industrial applications. These systems utilize advanced technologies to ensure the highest purity levels, which are critical for processes that require contaminant-free water, such as semiconductor manufacturing, pharmaceuticals, and laboratory research.

The core components of an ultra pure water purification system typically include pre-treatment stages, reverse osmosis (RO), deionization (DI), and ultrafiltration (UF). Understanding each stage is crucial for optimizing the purification process.

1. **Pre-treatment**: This initial step is vital for removing larger particles and sediments to protect downstream components. Common pre-treatment methods involve multimedia filtration, activated carbon adsorption, and microfiltration, ensuring that the water entering the RO system is free from larger impurities.

2. **Reverse Osmosis (RO)**: RO is a widely used technology in ultra pure water systems. It employs a semi-permeable membrane to remove dissolved ions, organic molecules, and other impurities from water. The effectiveness of RO in reducing Total Dissolved Solids (TDS) makes it a cornerstone of ultra pure water production.

3. **Deionization (DI)**: Following RO, deionization further polishes the water by removing ionic impurities. This step typically utilizes ion exchange resins to replace unwanted ions with hydrogen and hydroxide ions, ensuring that the water achieves a high level of purity.

4. **Ultrafiltration (UF)**: This is often used as a final polishing step. UF membranes can filter out bacteria and larger particles, providing an additional layer of protection against contamination before the water enters the storage or distribution system.

The benefits of ultra pure water purification systems are extensive. They enhance product quality by ensuring that impurities do not interfere with critical processes. This is particularly important in industries such as semiconductor manufacturing, where even minute levels of contaminants can lead to defects in microchips. In pharmaceuticals, ultra pure water is essential for meeting stringent regulatory standards, ensuring safety and efficacy in drug production.

Moreover, implementing an ultra pure water purification system can lead to significant cost savings over time. By reducing the need for extensive maintenance and reprocessing due to contamination, businesses can improve operational efficiency and reduce waste.

In summary, ultra pure water purification systems play a vital role in various industrial sectors by delivering high-quality, contaminant-free water essential for critical applications. By understanding the components and processes involved, businesses can make informed decisions that enhance their operational performance and product quality.

The core components of an ultra pure water purification system typically include pre-treatment stages, reverse osmosis (RO), deionization (DI), and ultrafiltration (UF). Understanding each stage is crucial for optimizing the purification process.

1. **Pre-treatment**: This initial step is vital for removing larger particles and sediments to protect downstream components. Common pre-treatment methods involve multimedia filtration, activated carbon adsorption, and microfiltration, ensuring that the water entering the RO system is free from larger impurities.

2. **Reverse Osmosis (RO)**: RO is a widely used technology in ultra pure water systems. It employs a semi-permeable membrane to remove dissolved ions, organic molecules, and other impurities from water. The effectiveness of RO in reducing Total Dissolved Solids (TDS) makes it a cornerstone of ultra pure water production.

3. **Deionization (DI)**: Following RO, deionization further polishes the water by removing ionic impurities. This step typically utilizes ion exchange resins to replace unwanted ions with hydrogen and hydroxide ions, ensuring that the water achieves a high level of purity.

4. **Ultrafiltration (UF)**: This is often used as a final polishing step. UF membranes can filter out bacteria and larger particles, providing an additional layer of protection against contamination before the water enters the storage or distribution system.

The benefits of ultra pure water purification systems are extensive. They enhance product quality by ensuring that impurities do not interfere with critical processes. This is particularly important in industries such as semiconductor manufacturing, where even minute levels of contaminants can lead to defects in microchips. In pharmaceuticals, ultra pure water is essential for meeting stringent regulatory standards, ensuring safety and efficacy in drug production.

Moreover, implementing an ultra pure water purification system can lead to significant cost savings over time. By reducing the need for extensive maintenance and reprocessing due to contamination, businesses can improve operational efficiency and reduce waste.

In summary, ultra pure water purification systems play a vital role in various industrial sectors by delivering high-quality, contaminant-free water essential for critical applications. By understanding the components and processes involved, businesses can make informed decisions that enhance their operational performance and product quality.