Understanding Ultra Pure Water Purification Systems: A Comprehensive Guide for Industrial Applications

Time:

Dec 19,2025

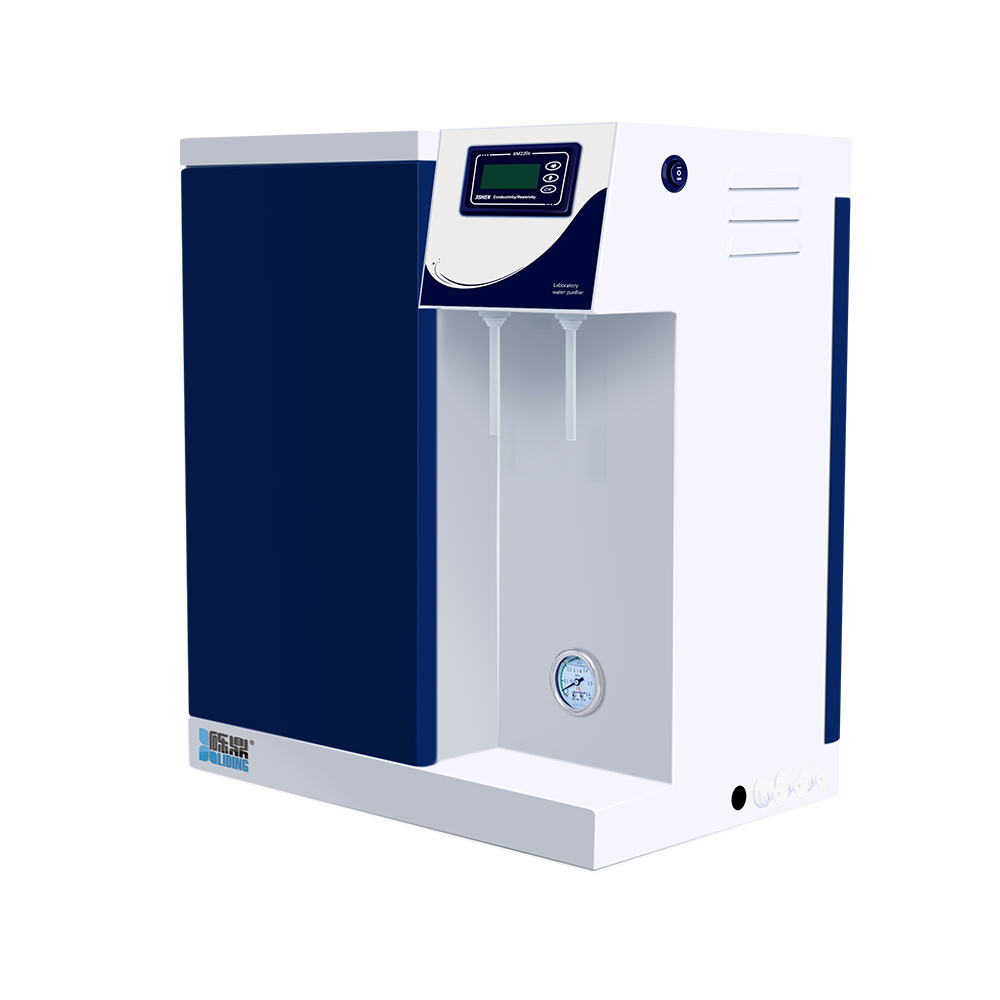

In various industrial applications, the demand for ultra pure water has become crucial due to the increasing need for high-quality water in processes such as semiconductor manufacturing, pharmaceuticals, and laboratory research. An ultra pure water purification system is designed to remove impurities to an extent that the final product meets or exceeds the stringent requirements of these industries.

At the core of an ultra pure water purification system are several advanced technologies that work in tandem to achieve the desired purity levels. Commonly employed methods include reverse osmosis (RO), deionization (DI), and ultrafiltration (UF). RO is particularly effective in removing dissolved salts and larger molecules, while DI systems utilize ion exchange resins to eliminate ionic impurities. Ultrafiltration serves as a pre-treatment step, filtering out particulate matter and microorganisms before the water undergoes further purification.

The operational benefits of implementing an ultra pure water purification system are manifold. Firstly, such systems significantly reduce the total dissolved solids (TDS) in water, ensuring that the impurities do not interfere with sensitive industrial processes. This is especially important in industries where even minute levels of contaminants can lead to product defects or functional failures. Secondly, ultra pure water systems can help streamline operations, as they minimize the need for extensive water treatment processes, thus saving time and resources.

Furthermore, ultra pure water is crucial for maintaining equipment longevity and efficiency. In the semiconductor industry, for example, even trace amounts of contaminants can damage delicate wafers during fabrication. By utilizing an ultra pure water purification system, manufacturers can protect their equipment and enhance product consistency, ultimately leading to improved performance and profitability.

When selecting an ultra pure water purification system, it is essential to consider factors such as flow rate, space constraints, and the specific purity needs of your application. Additionally, regular maintenance and monitoring are vital to ensure optimal performance over time. Keeping the system well-maintained not only extends its lifespan but also ensures that the water quality remains consistently high.

In conclusion, ultra pure water purification systems play a pivotal role in various industrial sectors by providing the high-purity water necessary for critical processes. Understanding the technologies involved and the benefits they offer can help industries make informed decisions, ultimately leading to enhanced operational efficiency and product quality. Whether you are upgrading an existing system or implementing a new one, investing in a reliable ultra pure water purification system is essential for meeting modern industrial demands.

At the core of an ultra pure water purification system are several advanced technologies that work in tandem to achieve the desired purity levels. Commonly employed methods include reverse osmosis (RO), deionization (DI), and ultrafiltration (UF). RO is particularly effective in removing dissolved salts and larger molecules, while DI systems utilize ion exchange resins to eliminate ionic impurities. Ultrafiltration serves as a pre-treatment step, filtering out particulate matter and microorganisms before the water undergoes further purification.

The operational benefits of implementing an ultra pure water purification system are manifold. Firstly, such systems significantly reduce the total dissolved solids (TDS) in water, ensuring that the impurities do not interfere with sensitive industrial processes. This is especially important in industries where even minute levels of contaminants can lead to product defects or functional failures. Secondly, ultra pure water systems can help streamline operations, as they minimize the need for extensive water treatment processes, thus saving time and resources.

Furthermore, ultra pure water is crucial for maintaining equipment longevity and efficiency. In the semiconductor industry, for example, even trace amounts of contaminants can damage delicate wafers during fabrication. By utilizing an ultra pure water purification system, manufacturers can protect their equipment and enhance product consistency, ultimately leading to improved performance and profitability.

When selecting an ultra pure water purification system, it is essential to consider factors such as flow rate, space constraints, and the specific purity needs of your application. Additionally, regular maintenance and monitoring are vital to ensure optimal performance over time. Keeping the system well-maintained not only extends its lifespan but also ensures that the water quality remains consistently high.

In conclusion, ultra pure water purification systems play a pivotal role in various industrial sectors by providing the high-purity water necessary for critical processes. Understanding the technologies involved and the benefits they offer can help industries make informed decisions, ultimately leading to enhanced operational efficiency and product quality. Whether you are upgrading an existing system or implementing a new one, investing in a reliable ultra pure water purification system is essential for meeting modern industrial demands.

RELATED NEWS