Understanding Ultra Pure Water Machines: Essential for Industrial Water Treatment

Time:

Nov 19,2025

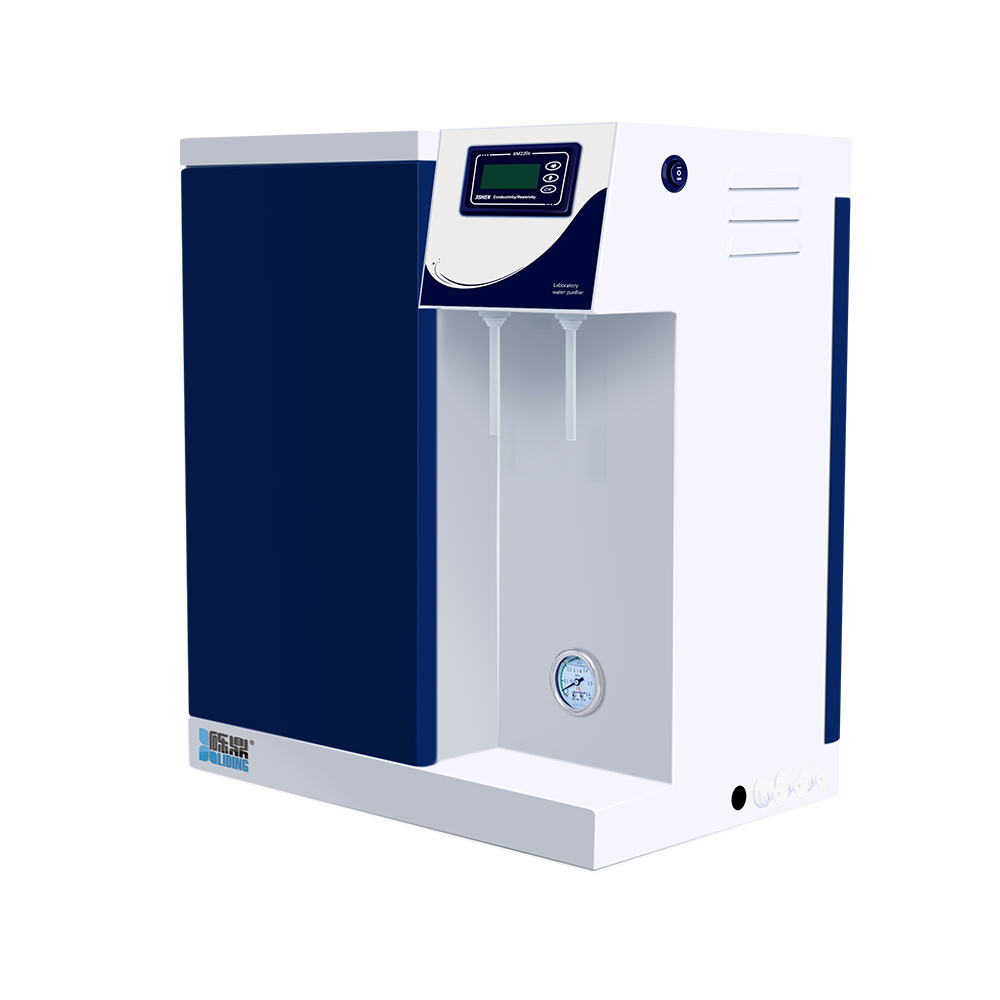

Ultra pure water machines play a crucial role in advanced water treatment processes, particularly in industries that require the highest quality of water for their operations. These machines are designed to produce water that meets or exceeds stringent purity standards, making them essential for applications in pharmaceuticals, electronics manufacturing, and laboratories.

The process of creating ultra pure water typically involves several stages of purification, including reverse osmosis, deionization, and ultraviolet light treatment. Each of these processes works to remove impurities such as dissolved solids, microorganisms, and organic contaminants, ensuring that the final product is free from any substances that could compromise quality or performance.

One of the primary advantages of using ultra pure water machines is their ability to produce water with very low levels of total dissolved solids (TDS). In many industrial applications, even trace levels of contaminants can lead to significant issues, including equipment damage, product contamination, and reduced efficiency. By utilizing ultra pure water machines, businesses can mitigate these risks and ensure that their manufacturing processes run smoothly.

Another key benefit of ultra pure water machines is their versatility. They can be tailored to meet the specific needs of various industries, allowing for customizable solutions that address unique water quality requirements. Whether it's for semiconductor fabrication, pharmaceutical production, or laboratory testing, these machines can be configured to deliver the precise quality of water needed for optimal results.

Moreover, ultra pure water machines are equipped with advanced monitoring systems that provide real-time data on water quality. This feature is vital for industries operating under strict regulatory standards, as it enables continuous oversight and guarantees compliance. By having access to immediate feedback on water purity, companies can quickly address any issues that may arise, thus maintaining the integrity of their operations.

In addition to their functional benefits, ultra pure water machines contribute to sustainable practices in water management. By employing highly efficient purification techniques, these machines reduce water wastage and promote the responsible use of resources. This is particularly important as industries face increasing pressure to adhere to environmental regulations and corporate sustainability goals.

In conclusion, ultra pure water machines are indispensable in the realm of industrial water treatment. Their ability to produce exceptionally high-quality water, coupled with their adaptability and real-time monitoring capabilities, makes them a valuable asset for any organization. As industries continue to evolve and demand greater standards, the role of ultra pure water machines will undoubtedly remain pivotal in ensuring operational excellence and product integrity.

The process of creating ultra pure water typically involves several stages of purification, including reverse osmosis, deionization, and ultraviolet light treatment. Each of these processes works to remove impurities such as dissolved solids, microorganisms, and organic contaminants, ensuring that the final product is free from any substances that could compromise quality or performance.

One of the primary advantages of using ultra pure water machines is their ability to produce water with very low levels of total dissolved solids (TDS). In many industrial applications, even trace levels of contaminants can lead to significant issues, including equipment damage, product contamination, and reduced efficiency. By utilizing ultra pure water machines, businesses can mitigate these risks and ensure that their manufacturing processes run smoothly.

Another key benefit of ultra pure water machines is their versatility. They can be tailored to meet the specific needs of various industries, allowing for customizable solutions that address unique water quality requirements. Whether it's for semiconductor fabrication, pharmaceutical production, or laboratory testing, these machines can be configured to deliver the precise quality of water needed for optimal results.

Moreover, ultra pure water machines are equipped with advanced monitoring systems that provide real-time data on water quality. This feature is vital for industries operating under strict regulatory standards, as it enables continuous oversight and guarantees compliance. By having access to immediate feedback on water purity, companies can quickly address any issues that may arise, thus maintaining the integrity of their operations.

In addition to their functional benefits, ultra pure water machines contribute to sustainable practices in water management. By employing highly efficient purification techniques, these machines reduce water wastage and promote the responsible use of resources. This is particularly important as industries face increasing pressure to adhere to environmental regulations and corporate sustainability goals.

In conclusion, ultra pure water machines are indispensable in the realm of industrial water treatment. Their ability to produce exceptionally high-quality water, coupled with their adaptability and real-time monitoring capabilities, makes them a valuable asset for any organization. As industries continue to evolve and demand greater standards, the role of ultra pure water machines will undoubtedly remain pivotal in ensuring operational excellence and product integrity.

RELATED NEWS