Common Misconceptions About Ultra Pure Water Systems Debunked

Time:

Jul 15,2025

Common Misconceptions About Ultra Pure Water Systems Debunked

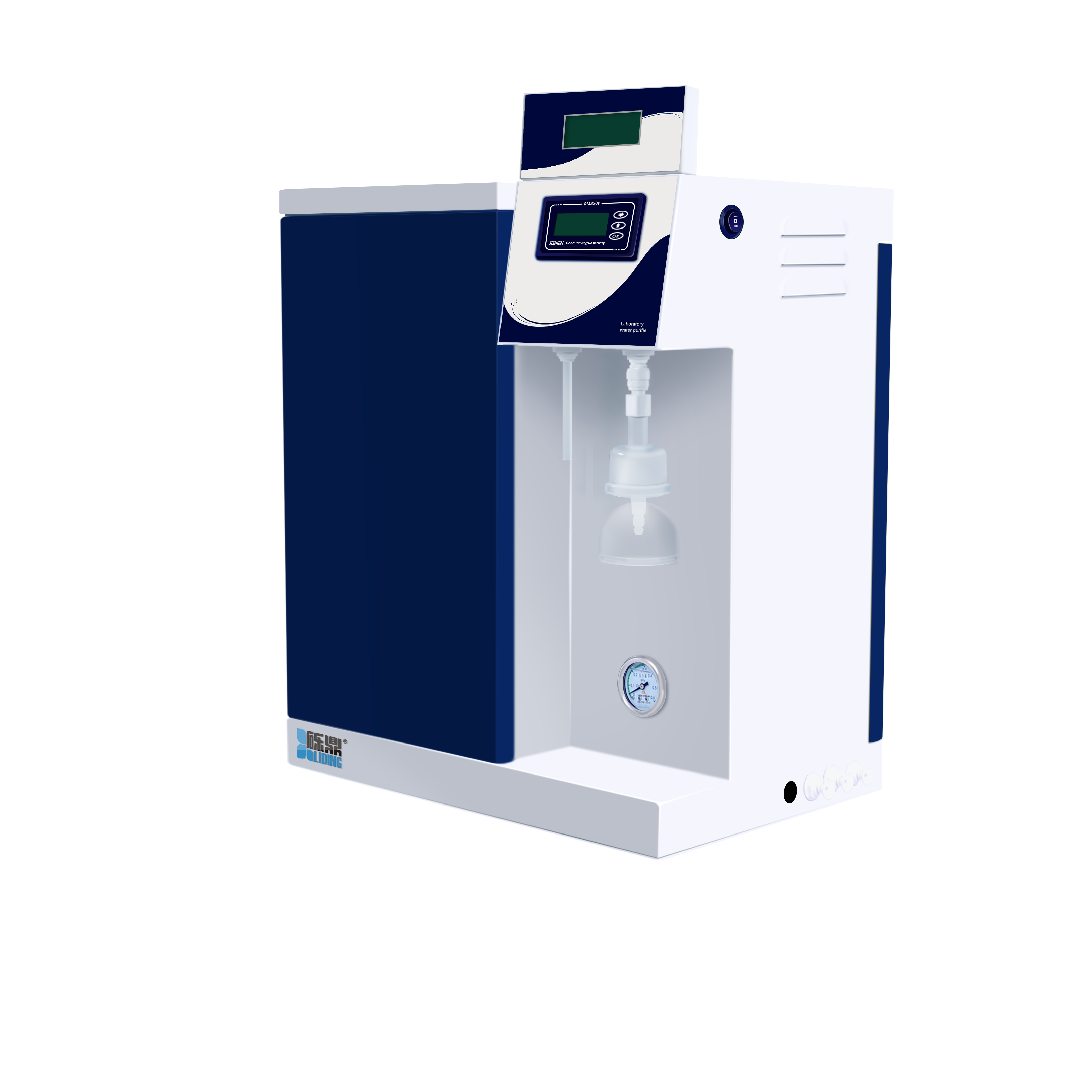

Introduction to Ultra Pure Water Systems

In today’s rapidly advancing technological landscape, the need for ultra pure water (UPW) systems is more critical than ever. These systems play a vital role in various industries, including pharmaceuticals, electronics, and biotechnology. However, despite their importance, several misconceptions persist around their operation and effectiveness. In this article, we will explore and debunk these myths, providing a clearer understanding of ultra pure water systems.

What is Ultra Pure Water and Why is it Important?

Ultra pure water is water that has been treated to remove impurities, making it suitable for sensitive applications. It typically has a resistivity of 18.2 megohm-cm, and contains minimal Total Dissolved Solids (TDS). This level of purity is crucial for industries where contaminants can lead to significant product failures, such as in semiconductor manufacturing or pharmaceutical production.

Definition of Ultra Pure Water

Ultra pure water is often produced through processes such as reverse osmosis, deionization, and distillation. The goal is to eliminate not only physical contaminants but also chemical and biological impurities.

The Role of Ultra Pure Water Systems in Various Industries

1. **Pharmaceutical Manufacturing**: In the pharmaceutical industry, UPW is essential for producing drugs safely and effectively. Contaminants can alter drug composition, impacting efficacy and safety.

2. **Semiconductor Fabrication**: The semiconductor industry requires ultra pure water for cleaning wafers. Any impurities can cause defects in the microchips, leading to costly failures.

3. **Laboratories**: In research settings, the reliability of experiments often hinges on the quality of water used. UPW ensures that experimental results are not skewed by contaminants.

Myth 1: Ultra Pure Water Systems are Only for High-Tech Industries

One prevailing myth is that ultra pure water systems are exclusively beneficial for high-tech industries. While these sectors certainly benefit the most from ultra pure water, many other industries can also reap significant advantages.

Broader Applications of Ultra Pure Water Systems

- **Food and Beverage**: In the food industry, ultra pure water is crucial for ensuring product safety and quality. It is used in processing, cooking, and cleaning applications.

- **Cosmetics**: The cosmetics industry uses UPW to avoid contaminants that could affect product consistency and safety.

Myth 2: Ultra Pure Water is Too Expensive to Produce

Another misconception revolves around the cost of producing ultra pure water. Many believe that the operational and maintenance costs of ultra pure water systems are prohibitively high.

The Cost-Effectiveness of Ultra Pure Water Systems

While the initial investment in an ultra pure water system can be significant, the long-term savings and benefits can outweigh the costs:

- **Reduced Waste**: UPW systems can minimize waste and rework, particularly in manufacturing processes.

- **Enhanced Product Quality**: Improved product quality can lead to higher customer satisfaction and reduced returns.

Myth 3: Ultra Pure Water Systems Require Constant Supervision

Some believe that ultra pure water systems demand constant monitoring and intervention, making them cumbersome to operate.

Automation and Monitoring Technologies

Modern ultra pure water systems are equipped with advanced monitoring and automation technologies that minimize human intervention:

- **Real-Time Monitoring**: Many systems offer real-time monitoring of water purity, allowing for immediate adjustments.

- **Automated Maintenance Alerts**: Systems can alert operators to maintenance needs, ensuring smooth operation without constant supervision.

Myth 4: All Water Purification Systems Produce Ultra Pure Water

Not all water purification systems are created equal. A common misunderstanding is that standard filtration or purification systems can achieve ultra pure water levels.

Understanding Different Water Purification Techniques

- **Reverse Osmosis**: While effective at removing many impurities, reverse osmosis alone does not achieve ultra pure water quality without further treatment.

- **Deionization**: This process is essential for achieving ultra purity, as it removes ionic contaminants that other methods may miss.

Myth 5: Ultra Pure Water Systems are Difficult to Maintain

Maintenance often deters industries from investing in ultra pure water systems due to the belief that they are complex to maintain.

Simple Maintenance Practices for Ultra Pure Water Systems

- **Regular Cleaning**: Establishing a routine cleaning schedule can significantly extend the lifespan of the system components.

- **Scheduled Inspections**: Conducting regular inspections helps identify potential issues before they escalate, ensuring optimal performance.

Myth 6: Ultra Pure Water Has No Nutritional Value

Some people think that ultra pure water, due to its lack of minerals, is not beneficial for health.

The Role of Ultra Pure Water in Health and Industry

While it is true that ultra pure water lacks minerals, its primary purpose is to serve industrial applications rather than human consumption. In specific scenarios, such as medical procedures or laboratory environments, the purity level is crucial to avoid contamination.

Benefits of Ultra Pure Water Systems

Understanding the misconceptions is vital, but recognizing the advantages of investing in ultra pure water systems is equally important.

Enhanced Operational Efficiency

Ultra pure water systems contribute to operational efficiency by ensuring high-quality water supply, which reduces downtime and product failures.

Compliance with Industry Standards

Many industries require adherence to strict regulatory standards regarding water quality. Ultra pure water systems help businesses meet these standards, avoiding legal penalties.

Choosing the Right Ultra Pure Water System

Selecting the appropriate ultra pure water system for your needs can be challenging. Consider the following factors:

Assessing Your Needs

- **Flow Rate Requirements**: Determine the volume of water needed for your operations.

- **Purity Levels Required**: Different applications may require varying levels of purity.

Consulting with Experts

Engaging with water treatment professionals can assist in selecting the right system and customizing it for your application.

FAQs About Ultra Pure Water Systems

1. What makes ultra pure water different from regular purified water?

Ultra pure water undergoes extensive purification processes to remove virtually all contaminants, achieving a resistivity of 18.2 megohm-cm, while regular purified water may still contain some impurities.

2. How often do I need to maintain my ultra pure water system?

Maintenance frequency depends on usage, but regular cleaning and inspections should be conducted every few months to ensure optimal performance.

3. Can ultra pure water be used for drinking?

While ultra pure water is safe, it is not typically recommended for drinking due to the absence of minerals that our bodies need.

4. How do I know if my ultra pure water system is functioning properly?

Using a conductivity meter or resistivity meter can help monitor water purity levels. Any significant changes might indicate a malfunction.

5. Is it possible to retrofit an existing water system to achieve ultra purity?

Yes, existing systems can often be upgraded with additional filtration technologies to enhance water purity.

Conclusion

Ultra pure water systems are integral to numerous industries, yet several misconceptions hinder their adoption. By debunking these myths, we highlight the critical role that ultra pure water plays in ensuring product quality and operational efficiency. Understanding the benefits, maintenance needs, and appropriate applications of these systems can empower industries to make informed decisions about their water purification requirements. Investing in an ultra pure water system is not only a step towards enhancing product integrity but also a commitment to maintaining high industry standards.

RELATED NEWS