The Essential Guide to Deionized Water in Industrial Water Treatment

Time:

Jul 06,2025

Deionized water, often referred to as DI water, is water that has had its mineral ions removed, such as sodium, calcium, iron, and copper. This process is essential in industries where high purity is a must, as impurities can lead to corrosion, scaling, or contamination in sensitive processes and equipment.

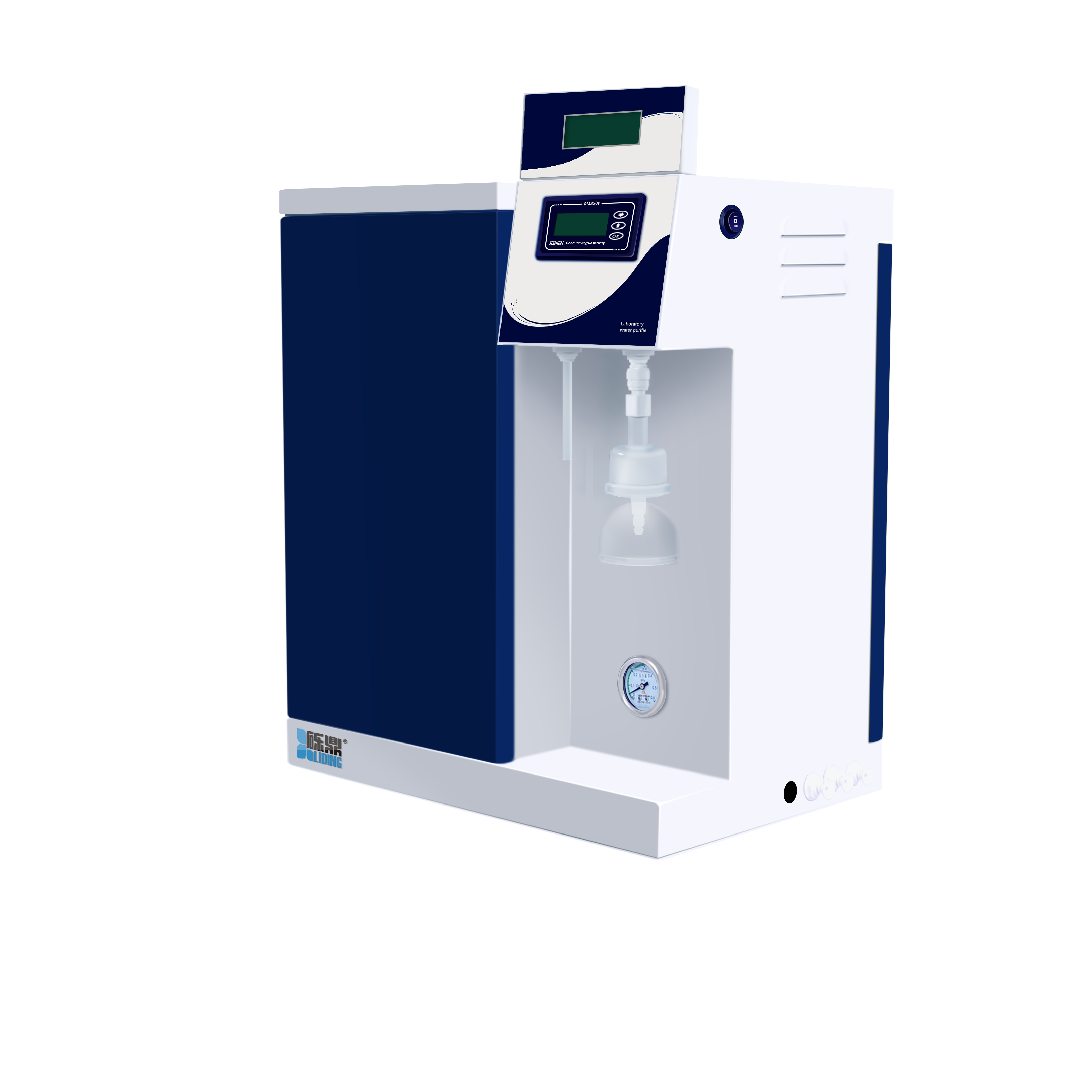

The production of deionized water typically involves ion exchange processes where water is passed through resin beds that attract and remove charged ions. This method is vital for achieving the high levels of purity required in various applications, such as semiconductor manufacturing, pharmaceuticals, and laboratory research.

In an industrial setting, using deionized water can greatly enhance the efficiency and longevity of equipment. For instance, in cooling systems, using DI water minimizes scaling on heat exchangers, thereby improving heat transfer efficiency and reducing maintenance costs. Similarly, in cleaning processes, deionized water is preferred due to its ability to dissolve contaminants without leaving residues that could affect product quality.

It's important to note that while deionized water is highly purified, it is not the same as distilled water. Distillation involves boiling water and condensing the steam, which removes impurities differently than deionization. Understanding this difference is critical when selecting water treatment methods for specific applications.

Furthermore, the use of deionized water is not limited to manufacturing processes. It is also employed in laboratories for experiments that require precise measurements and reactions, where even minute levels of impurities can alter results. In these contexts, the quality of deionized water is paramount, and regular testing is advisable to ensure its effectiveness.

To maintain the quality of deionized water, proper storage and handling are essential. Exposure to air can lead to re-ionization, where the water absorbs ions from the environment. Thus, DI water should be stored in tightly sealed containers, away from any potential sources of contamination.

In summary, deionized water plays a critical role in various industrial applications, promoting equipment efficiency and ensuring product quality. Understanding its production methods, benefits, and proper handling is vital for industries that rely on high-purity water solutions.

The production of deionized water typically involves ion exchange processes where water is passed through resin beds that attract and remove charged ions. This method is vital for achieving the high levels of purity required in various applications, such as semiconductor manufacturing, pharmaceuticals, and laboratory research.

In an industrial setting, using deionized water can greatly enhance the efficiency and longevity of equipment. For instance, in cooling systems, using DI water minimizes scaling on heat exchangers, thereby improving heat transfer efficiency and reducing maintenance costs. Similarly, in cleaning processes, deionized water is preferred due to its ability to dissolve contaminants without leaving residues that could affect product quality.

It's important to note that while deionized water is highly purified, it is not the same as distilled water. Distillation involves boiling water and condensing the steam, which removes impurities differently than deionization. Understanding this difference is critical when selecting water treatment methods for specific applications.

Furthermore, the use of deionized water is not limited to manufacturing processes. It is also employed in laboratories for experiments that require precise measurements and reactions, where even minute levels of impurities can alter results. In these contexts, the quality of deionized water is paramount, and regular testing is advisable to ensure its effectiveness.

To maintain the quality of deionized water, proper storage and handling are essential. Exposure to air can lead to re-ionization, where the water absorbs ions from the environment. Thus, DI water should be stored in tightly sealed containers, away from any potential sources of contamination.

In summary, deionized water plays a critical role in various industrial applications, promoting equipment efficiency and ensuring product quality. Understanding its production methods, benefits, and proper handling is vital for industries that rely on high-purity water solutions.