Exploring the Process Behind Ultrapure Water Purification Systems: A Comprehensive Guide

Time:

Jul 19,2025

Exploring the Process Behind Ultrapure Water Purification Systems

Table of Contents

- 1. Introduction to Ultrapure Water Purification

- 2. The Importance of Ultrapure Water in Various Industries

- 3. Key Technologies Used in Ultrapure Water Purification

- 4. The Ultrapure Water Purification Process

- 5. Applications of Ultrapure Water

- 6. Challenges in Ultrapure Water Production

- 7. The Future of Ultrapure Water Purification Systems

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Ultrapure Water Purification

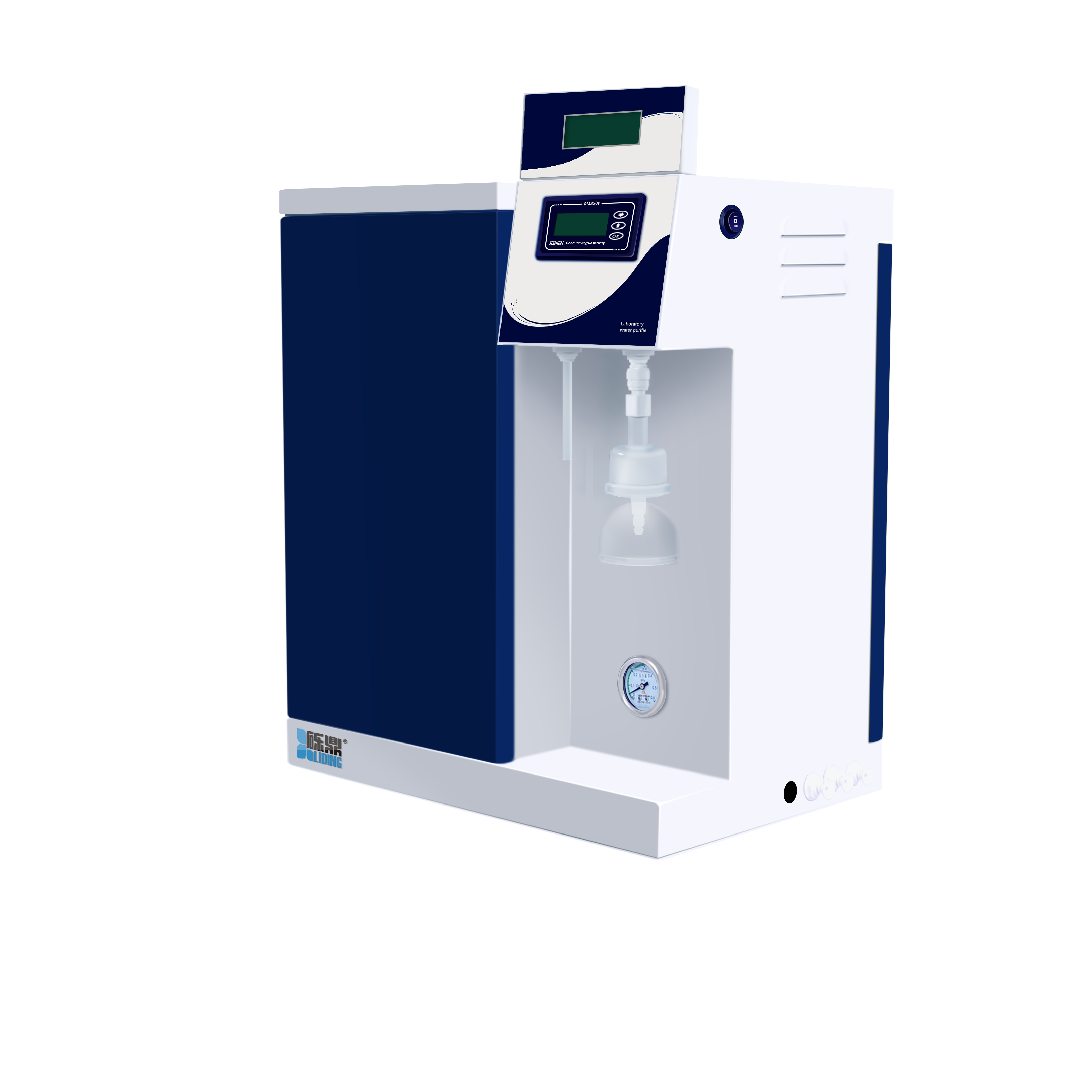

Ultrapure water is essential for many applications, especially in industries that require high-quality water, such as pharmaceuticals, electronics, and power generation. **Ultrapure water purification systems** are designed to remove virtually all contaminants, including dissolved salts, organic molecules, and microorganisms. In this article, we will explore the technologies and processes that make ultrapure water purification possible, shedding light on its significance and future developments.

2. The Importance of Ultrapure Water in Various Industries

The demand for ultrapure water continues to grow, driven by the increasing need to maintain quality and safety standards in a variety of sectors.

2.1 Pharmaceutical Industry

In the pharmaceutical industry, ultrapure water is critical for manufacturing medications and vaccines. **Contaminated water can lead to compromised products**, which may affect patient safety and lead to costly recalls.

2.2 Semiconductor Manufacturing

The semiconductor industry relies on ultrapure water to clean wafers and other components. **Even minute levels of contaminants** can result in defects, making the production of chips highly sensitive to water purity.

2.3 Power Generation

In power plants, ultrapure water is used in boiler systems to minimize corrosion and scaling. The **integrity of the machinery** heavily depends on the quality of water used, as impurities can lead to significant operational issues.

3. Key Technologies Used in Ultrapure Water Purification

Various technologies work together to achieve the high levels of purity required for ultrapure water. Understanding these methods is key to appreciating how ultrapure water is produced.

3.1 Reverse Osmosis

Reverse osmosis (RO) is one of the most widely used techniques for ultrapure water production. It works by forcing water through a semi-permeable membrane that blocks contaminants while allowing water molecules to pass.

3.2 Ion Exchange

Ion exchange is another critical technology in ultrapure water purification. This process involves exchanging undesirable ions in the water with more benign ions from a resin. The result is water that is free from dissolved ions, contributing significantly to overall purity.

3.3 Distillation

Distillation involves heating water to create steam and then cooling it back into liquid form. **This method effectively removes impurities and is often used in conjunction with other purification processes** to achieve the desired level of purity.

3.4 Ultrafiltration

Ultrafiltration (UF) employs a membrane to separate particles based on size. This technology is effective at removing suspended solids and macromolecules, making it an essential step in many ultrapure water systems.

4. The Ultrapure Water Purification Process

The purification of ultrapure water typically involves several stages, each designed to remove specific contaminants and enhance overall water quality.

4.1 Pre-treatment Steps

Before the main purification process begins, pre-treatment steps are crucial. These may include sediment filtration, activated carbon filtration, and softening, which help reduce the load on the subsequent purification stages.

4.2 Main Purification Techniques

The main purification techniques, such as reverse osmosis and ion exchange, are employed to achieve the desired purity level. These methods work synergistically to remove nearly all contaminants present in the water.

4.3 Post-treatment and Monitoring

After the main purification stages, post-treatment processes such as UV sterilization or additional ion exchange may be applied to further ensure water quality. Continuous monitoring through advanced sensors and systems ensures that water purity remains within the required standards.

5. Applications of Ultrapure Water

Ultrapure water is utilized in various applications where the presence of impurities can have severe consequences.

5.1 Laboratory Use

In laboratories, ultrapure water is critical for experiments and analyses, ensuring that results are not compromised by contaminants.

5.2 Medical Applications

Medical devices and procedures often require ultrapure water for cleaning and sterilization, highlighting the necessity of maintaining high purity levels.

6. Challenges in Ultrapure Water Production

Despite advancements in purification technologies, challenges remain in producing ultrapure water efficiently and cost-effectively.

6.1 Regulatory Compliance

Adhering to stringent regulatory standards is a significant challenge for manufacturers. **Constant changes in regulations** require facilities to adapt their processes and technologies, which can be costly.

6.2 Resource Management

The production of ultrapure water requires substantial energy and resources. Balancing sustainability with high output quality is an ongoing challenge for the industry.

7. The Future of Ultrapure Water Purification Systems

As technology evolves, so too will the methods used to produce ultrapure water. Innovations such as **smart sensing technologies, advanced filtration materials, and energy-efficient systems** are paving the way for a more sustainable future in ultrapure water production.

8. Frequently Asked Questions (FAQs)

8.1 What is ultrapure water?

Ultrapure water is water that has been purified to high standards, removing almost all contaminants, including ions, microorganisms, and organic compounds.

8.2 How is ultrapure water produced?

Ultrapure water is produced through a combination of techniques, including reverse osmosis, ion exchange, distillation, and ultrafiltration.

8.3 What industries use ultrapure water?

Industries such as pharmaceuticals, semiconductor manufacturing, and power generation utilize ultrapure water for their processes.

8.4 What contaminants are removed during the purification process?

The purification process removes dissolved salts, organic compounds, suspended solids, and microorganisms.

8.5 What are the challenges in producing ultrapure water?

Challenges include regulatory compliance, resource management, and maintaining high purity levels in a cost-effective manner.

9. Conclusion

Ultrapure water purification systems play a vital role in ensuring the safety and effectiveness of various industrial applications. By understanding the technologies and processes behind ultrapure water production, we can appreciate its significance in today’s world. As we move forward, continuous advancements in purification technology will help address the challenges facing the industry, ensuring a sustainable and efficient supply of ultrapure water for generations to come.

RELATED NEWS