Understanding Ultra Pure Water Equipment: Essential Insights for Industrial Applications

Time:

Jul 18,2025

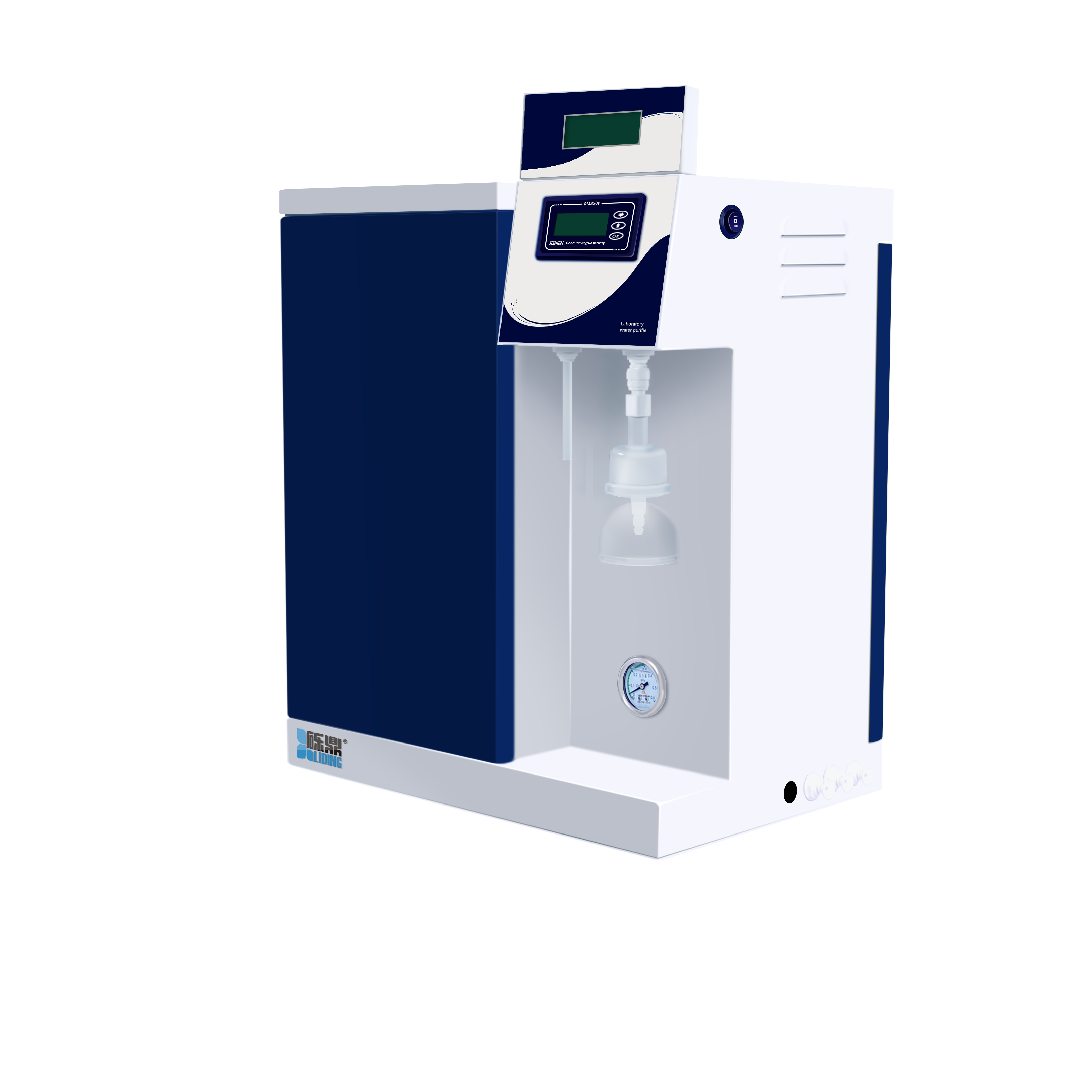

Ultra pure water equipment is specialized technology designed to produce highly purified water, free from contaminants, ions, and organic materials. This type of water is essential in various industrial applications, including semiconductor manufacturing, pharmaceuticals, and power generation, where even trace impurities can lead to significant operational issues or product defects.

The process of producing ultra pure water typically involves several stages of treatment. Initially, pre-treatment methods such as sedimentation and filtration remove larger particles and turbidity. This is followed by advanced filtration techniques, including reverse osmosis (RO) and deionization (DI). Reverse osmosis uses a semi-permeable membrane to effectively separate dissolved salts and contaminants from water, while deionization employs ion exchange resins to remove ionic impurities. These processes work in tandem to achieve the desired water purity levels.

In addition to RO and DI, other technologies such as ultraviolet (UV) light and ozonation may be employed to eliminate any remaining microorganisms and organic substances. Combining these methods ensures that the water meets or exceeds the stringent quality standards required in sensitive industrial operations.

The importance of ultra pure water cannot be overstated. For instance, in the semiconductor industry, the presence of contaminants in water can lead to defects in microchips, resulting in costly production losses. Similarly, in pharmaceuticals, the purity of water used in drug formulation and cleaning processes is crucial to ensuring product safety and efficacy.

Moreover, the effective use of ultra pure water equipment can lead to operational efficiencies and cost savings. By minimizing the need for chemical additives and reducing waste, companies can improve their environmental footprint. Additionally, maintaining high water purity levels can extend the lifespan of equipment and reduce maintenance costs.

However, selecting the right ultra pure water equipment involves understanding the specific requirements of your application. Factors such as water source quality, desired output purity, and production capacity should all be considered. Collaborating with experienced professionals can help ensure that the chosen system integrates seamlessly with existing processes and meets all regulatory standards.

In summary, ultra pure water equipment plays a critical role in various industrial sectors by providing the highest quality water necessary for sensitive applications. By understanding the processes involved in producing ultra pure water, industry professionals can make informed decisions that enhance productivity and ensure compliance with stringent quality requirements.

The process of producing ultra pure water typically involves several stages of treatment. Initially, pre-treatment methods such as sedimentation and filtration remove larger particles and turbidity. This is followed by advanced filtration techniques, including reverse osmosis (RO) and deionization (DI). Reverse osmosis uses a semi-permeable membrane to effectively separate dissolved salts and contaminants from water, while deionization employs ion exchange resins to remove ionic impurities. These processes work in tandem to achieve the desired water purity levels.

In addition to RO and DI, other technologies such as ultraviolet (UV) light and ozonation may be employed to eliminate any remaining microorganisms and organic substances. Combining these methods ensures that the water meets or exceeds the stringent quality standards required in sensitive industrial operations.

The importance of ultra pure water cannot be overstated. For instance, in the semiconductor industry, the presence of contaminants in water can lead to defects in microchips, resulting in costly production losses. Similarly, in pharmaceuticals, the purity of water used in drug formulation and cleaning processes is crucial to ensuring product safety and efficacy.

Moreover, the effective use of ultra pure water equipment can lead to operational efficiencies and cost savings. By minimizing the need for chemical additives and reducing waste, companies can improve their environmental footprint. Additionally, maintaining high water purity levels can extend the lifespan of equipment and reduce maintenance costs.

However, selecting the right ultra pure water equipment involves understanding the specific requirements of your application. Factors such as water source quality, desired output purity, and production capacity should all be considered. Collaborating with experienced professionals can help ensure that the chosen system integrates seamlessly with existing processes and meets all regulatory standards.

In summary, ultra pure water equipment plays a critical role in various industrial sectors by providing the highest quality water necessary for sensitive applications. By understanding the processes involved in producing ultra pure water, industry professionals can make informed decisions that enhance productivity and ensure compliance with stringent quality requirements.

RELATED NEWS